Embarking on any building project, whether it’s a gleaming new skyscraper, a cozy residential renovation, or a vital piece of public infrastructure, feels a lot like setting sail into completely uncharted waters. Without a sturdy vessel and, crucially, a meticulously plotted course, you’ll likely find yourself drifting, buffeted by unforeseen squalls, or worse, completely shipwrecked on the rocks of budget overruns and schedule delays. To truly steer your project toward the calm harbors of success, a robust, detailed plan isn’t just helpful; it’s absolutely non-negotiable. This isn’t just about ticking boxes, it’s about crafting a vision into a tangible, actionable roadmap, ensuring every brick laid and every beam raised serves a purpose. It’s an adventure, certainly, but one that demands foresight and strategic thinking. So, let’s chart a course, shall we, through the essential steps that will transform your ambitious idea into a triumphant reality. You won’t regret the upfront effort, trust me. It pays dividends down the line. It really does.

Successful low-energy building design hinges on careful planning. Focus360 Energy can help.

1. Define Your Project’s Purpose and Scope: The North Star of Your Endeavor

Before you even think about sketching a single line or calling a single contractor, you absolutely must clarify what you’re setting out to achieve. This initial step, often underestimated, is the bedrock upon which all subsequent decisions are made. Ask yourself, really delve deep: What fundamental problem does this project solve? What specific value will it create? And what, precisely, are the non-negotiable deliverables? This isn’t just a philosophical exercise; it’s a practical necessity.

Imagine you’re building a new community center. You wouldn’t just say, ‘We need a community center.’ Oh no, you’d specify its intended services: a youth drop-in program, senior fitness classes, a multi-purpose hall for events. You’d outline its capacity—say, enough space for 200 people concurrently—and crucial design features like accessible ramps, soundproofed meeting rooms, and energy-efficient HVAC systems. Without these granular details, how would an architect know where to begin? How would a builder quote accurately? It’s simply impossible, creating a breeding ground for misunderstandings and costly revisions.

The Power of a Project Charter

A great way to formalize this initial thinking is through a Project Charter. Think of it as your project’s constitution. It’s a brief, authoritative document, typically just a page or two, that formally authorizes the project, defines its high-level objectives, identifies the primary stakeholders, and, most importantly, clearly establishes the project manager’s authority. This isn’t just for massive undertakings; even smaller projects benefit from this clarity. It gets everyone on the same page from the very beginning, ensuring that when discussions get heated or ideas start to wander, you can always refer back to this foundational document. It acts as a compass, true, but it’s also the project’s anchoring point.

Unpacking the ‘Scope’

The ‘scope’ isn’t just a fancy word; it’s the detailed blueprint of what is, and isn’t, part of your project. It includes all the work that needs to be done to deliver the project’s objectives, and equally important, what falls outside of its boundaries. For instance, if you’re renovating a kitchen, the scope might include new cabinets, countertops, and appliances, but explicitly exclude painting the adjacent dining room or upgrading the living room flooring. That clear delineation prevents scope creep, that insidious phenomenon where small, unplanned additions gradually inflate your budget and timeline. Every small addition feels innocuous at the time, but collectively, they can truly derail things. So, be firm with your scope, and be ready to politely push back on out-of-scope requests, you’ll thank yourself later.

Remember, a well-defined purpose and scope aren’t static declarations; they are living documents that guide every single decision, from material selection to contractor negotiations. Get this right, and you’ve already won half the battle. Get it wrong, and you’re already behind, potentially before the first shovel even breaks ground.

2. Conduct a Thorough Site Analysis: Knowing Your Ground

Understanding your project’s location isn’t merely paramount, it’s absolutely foundational. You can have the most brilliant architectural design, but if it clashes with the realities of your site, you’re in for a world of pain and expense. A comprehensive site analysis isn’t just a checklist; it’s an investigative deep dive, unearthing both potential challenges and exciting opportunities. It ensures your design is not just aesthetically pleasing, but also fundamentally feasible, efficient, and ultimately, safe.

Beyond the Surface: What to Investigate

Your analysis needs to go well beyond a quick glance. We’re talking about a multi-layered investigation:

-

Geotechnical Conditions: This is where you bring in the experts. Soil conditions are critical. Is the ground stable enough to support your structure? Are you dealing with expansive clays, bedrock, or perhaps an old landfill site? Geotechnical reports will detail bearing capacity, soil composition, the water table depth, and potential for settlement. I once saw a project held up for months because unexpected groundwater meant a complete redesign of the foundation system, adding millions to the budget. Don’t make that mistake.

-

Topography and Drainage: How does the land lie? What are the natural elevation changes? A topographical survey maps every contour, helping you understand natural drainage patterns. This isn’t just about preventing puddles; it’s crucial for stormwater management, preventing erosion, and sometimes, even dictating the most cost-effective placement of your building. Efficient drainage design can save a fortune in maintenance costs later on.

-

Existing Infrastructure: What’s already there? Roads, utility lines (water, sewer, electricity, gas, fiber optics)—are they adequate? Do they need upgrading? Where are the connection points? This phase often involves liaising with local utility companies, which can sometimes be a surprisingly complex dance of applications and approvals. You’d be amazed how many projects encounter delays because someone forgot to verify the actual capacity of the nearest electrical grid.

-

Environmental Considerations: This is a big one. Are there any protected species on site? Wetlands? Historical trees? What about potential contamination from previous uses? An Environmental Impact Assessment (EIA) might be required, assessing noise pollution, air quality impacts, and waste generation. Neglecting this can lead to massive fines, public outcry, and complete project halts. Seriously, you can’t afford to overlook this.

-

Regulatory and Legal Landscape: Zoning ordinances, building codes, setbacks, easements, historical preservation overlays—these are the rules of the game. Your design must comply. Are there any restrictive covenants on the land title? What about rights-of-way that could impact your access? Navigating this bureaucratic maze early prevents costly redesigns and legal battles down the road. It’s dense, yes, but utterly vital.

-

Accessibility and Surroundings: How will people and materials access the site during construction? What about after? Consider traffic patterns, public transport links, and proximity to residential areas. Construction noise and activity can significantly impact local communities, so understanding this helps in planning mitigation strategies and maintaining good neighborly relations.

Tools for a Deeper Look

Modern technology offers incredible tools for site analysis: drone surveys provide high-resolution aerial imagery and 3D models; Geographic Information Systems (GIS) layer vast amounts of spatial data; and advanced geological surveys can give you an X-ray view of what lies beneath. Leveraging these tools means you’re not just guessing; you’re making informed, data-driven decisions.

My team once acquired a prime piece of land, seemingly perfect. But a thorough site analysis, digging into historical records and commissioning an environmental survey, revealed an undocumented, disused fuel tank buried beneath what was slated to be the main entrance. Unearthing and remediating it added significant cost and a few weeks to the schedule, but imagine if we’d found it after pouring the foundations. The headache, cost, and delay would have been astronomically worse. It’s a powerful reminder: the ground beneath your feet holds many secrets, and it’s always best to discover them proactively. Always.

3. Develop a Work Breakdown Structure (WBS): Deconstructing Complexity

Once your project’s purpose is crystal clear and you’ve intimately familiarized yourself with the site, it’s time to tackle the monumental task itself. How do you eat an elephant? One bite at a time, right? That’s the core philosophy behind a Work Breakdown Structure, or WBS. It’s an invaluable tool, a hierarchical decomposition of the entire project scope into smaller, more manageable, and most importantly, clearly trackable work packages. This approach doesn’t just clarify roles and responsibilities; it’s a cornerstone for accurate cost estimation, realistic scheduling, and effective resource allocation. Think of it as creating an incredibly detailed, multi-layered map before embarking on a complex expedition.

The Hierarchical Magic of WBS

A WBS essentially breaks your project down into levels, moving from the general to the specific:

- Level 1: The Project Itself. This is the overall goal, e.g., ‘Construction of New Office Building.’

- Level 2: Major Deliverables. These are the primary components or phases, like ‘Foundation,’ ‘Structural Frame,’ ‘Building Enclosure,’ ‘Interior Fit-out,’ and ‘Site Work.’

- Level 3: Sub-Deliverables/Components. Under ‘Foundation,’ you might have ‘Excavation,’ ‘Footings,’ ‘Slab-on-Grade.’ Under ‘Interior Fit-out,’ perhaps ‘HVAC Installation,’ ‘Electrical Rough-in,’ ‘Partition Walls,’ ‘Finishes.’

- Level 4: Work Packages. These are the lowest level of the WBS, concrete, definable tasks that can be assigned to a specific team or individual, have a clear start and end, and a measurable outcome. For ‘Excavation,’ a work package might be ‘Mobilize Equipment,’ ‘Clear and Grub Site,’ ‘Dig Footing Trenches,’ ‘Backfill and Compact.’ Each work package should be small enough to be managed effectively, but large enough to avoid micromanagement.

Why Bother with a WBS?

The benefits of investing time in a robust WBS are manifold:

- Crystal Clear Scope: It provides an unambiguous understanding of all the work required, reducing ambiguity and preventing things from falling through the cracks. Everyone knows exactly what’s expected.

- Improved Estimation: By breaking down work into smaller packages, you can estimate costs and durations much more accurately. It’s easier to estimate the cost of digging trenches than the entire ‘foundation’ phase.

- Better Resource Allocation: You can clearly see what types of resources (labor, materials, equipment) are needed for each work package, making allocation more efficient.

- Clear Accountability: Each work package can be assigned to a specific team or person, fostering a sense of ownership and accountability.

- Risk Identification: Smaller tasks make it easier to identify potential risks specific to those activities rather than vague, overarching project risks.

- Foundation for Scheduling: The work packages become the building blocks for your project schedule, feeding directly into Gantt charts and critical path analyses.

Crafting Your WBS: A Practical Approach

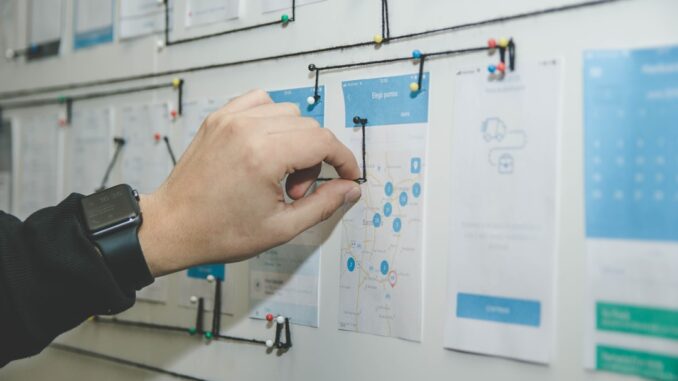

You can approach WBS creation in a few ways. A common method is ‘top-down,’ starting with the major deliverables and progressively breaking them down. Alternatively, a ‘bottom-up’ approach involves brainstorming all necessary activities and then grouping them into logical categories. Often, a combination works best, leveraging the collective wisdom of your project team and key stakeholders. It’s collaborative, you see. Everyone brings their expertise to the table, making the WBS more comprehensive and accurate.

Remember the 100% Rule: the WBS must include 100% of the work defined by the project scope and capture all deliverables, internal and external, in terms of the work to be completed, including project management. No detail too small, no stone left unturned. It’s truly your project’s skeleton, providing structure and support for everything that follows.

4. Establish a Realistic Schedule: The Rhythm of Progress

In the world of construction, time isn’t just money; it’s often huge money. Delays cascade, impacting not only labor costs and equipment rentals but also potentially incurring liquidated damages and straining client relationships. Therefore, developing a detailed, realistic project schedule isn’t merely a suggestion; it’s an absolute imperative. This isn’t just about listing tasks; it’s about understanding the intricate dance of dependencies, allocating sufficient time, and building in buffers for the inevitable curveballs. A well-structured schedule acts as your project’s timeline, the pulse that ensures timely completion and keeps everyone synchronized.

Methodologies for Mastering the Clock

Several robust methodologies can help you craft and manage your schedule:

-

Gantt Charts: These are perhaps the most widely recognized scheduling tools. A Gantt chart visually represents your project’s timeline, displaying tasks along a horizontal axis (time) and listing them vertically. Crucially, they illustrate task dependencies—which tasks must finish before others can begin—and clearly mark key milestones. They provide an easy-to-understand visual snapshot of project progress, making it simple to see where you are and where you should be. Everyone loves a good visual aid, don’t they?

-

Critical Path Method (CPM): This is where scheduling gets serious. CPM identifies the longest sequence of dependent activities that must be completed on time for the entire project to finish on schedule. Any delay to an activity on the critical path directly delays the entire project. CPM also highlights ‘float’ or ‘slack’—the amount of time an activity can be delayed without affecting the project’s overall completion date. Understanding your critical path allows you to focus your resources and attention on the tasks that truly matter most for timely delivery. It’s like finding the essential gears in a complex machine.

-

Program Evaluation and Review Technique (PERT): For projects with inherent uncertainties (which, let’s be honest, is most construction projects), PERT offers a more probabilistic approach. Instead of a single duration estimate for each task, PERT uses three: optimistic, most likely, and pessimistic. This allows for a weighted average, providing a more realistic expected duration and a better sense of schedule variability. It helps you factor in the ‘what ifs’ when exact timelines are a bit fuzzy.

-

Lean Construction Principles: Increasingly popular, lean principles focus on maximizing value while minimizing waste. Techniques like ‘pull planning’ and the ‘Last Planner System’ involve collaborative scheduling sessions with those who will actually perform the work, creating a more reliable and buy-in-driven schedule. It fosters a sense of collective ownership over the timeline, which is pretty powerful, wouldn’t you agree?

Factors that Shape Your Schedule

No schedule exists in a vacuum. Several factors will significantly influence its development and execution:

- Weather: Mother Nature cares little for your deadlines. Rain, snow, extreme heat, or high winds can halt or severely impede outdoor work. Building in weather contingency is smart, especially in regions with distinct seasons.

- Resource Availability: If your specialized welding team isn’t free until next month, or a critical material is on backorder, your schedule will shift. This highlights the interdependency of scheduling and resource planning.

- Permits and Inspections: Regulatory approvals and mandated inspections can cause delays if not managed proactively. The infamous ‘waiting for the inspector’ can eat up valuable days.

- Client Changes: Scope creep, even if small, can ripple through your schedule. Robust change management processes are crucial to assess the impact of changes and adjust the schedule accordingly.

- Subcontractor Performance: Your schedule is only as strong as your weakest link. Poor performance or delays from a subcontractor can throw your entire project off track.

Building Resilience into Your Schedule

Beyond just listing tasks, a truly effective schedule builds in resilience. This means incorporating reasonable buffer times, identifying potential choke points, and having contingency plans for critical path activities. Regularly track progress against your baseline schedule. Are you ahead, on track, or falling behind? This continuous monitoring allows for timely adjustments, whether it’s reallocating resources, working overtime, or even fast-tracking certain activities. It’s an ongoing process, a living document, not something you create once and then forget about. You’re constantly course-correcting, making small adjustments to stay true to your initial trajectory. It’s pretty satisfying when it all comes together, I must say.

5. Allocate Resources Wisely: The Engine of Productivity

Even the most meticulously planned project, with the clearest scope and the most robust schedule, will grind to a halt without the right resources, in the right place, at the right time. Effective resource management isn’t just key; it’s the very engine that drives productivity and keeps your project moving forward. This involves a thoughtful determination of all the labor, materials, equipment, and even financial capital needed for each task, from the smallest work package to the largest phase. Mismanaging resources leads to bottlenecks, idle crews, wasted materials, and, predictably, significant cost overruns and delays. It’s a tricky balancing act, but absolutely essential.

The Three Pillars of Resource Allocation

We typically categorize resources into three main areas, though financial resources underpin them all:

-

Human Resources (Labor):

- The Right People: This isn’t just about numbers; it’s about skill sets. Do you need highly specialized welders for a structural steel phase? General laborers for site clearing? Experienced project managers to oversee complex sub-sections? Your staffing plan needs to align the right expertise with the right tasks.

- Staffing Levels: Overstaffing leads to idle time and unnecessary costs; understaffing creates bottlenecks and delays. Resource leveling techniques help you smooth out peaks and valleys in demand, ensuring a consistent workflow and optimal utilization of your workforce.

- Subcontractors: Often, specialized tasks are outsourced. Planning for subcontractor engagement includes vetting, contract negotiation, scheduling their work, and ensuring their deliverables integrate seamlessly with your overall plan. Coordinating multiple subcontractors, each with their own schedules and demands, can feel like herding cats, but it’s crucial.

- Safety and Training: Ensuring your team is properly trained and equipped, not just for the task at hand but also for site safety, is non-negotiable. A skilled, safe workforce is an efficient workforce.

-

Material Resources:

- Procurement Strategy: How will you acquire everything from concrete and rebar to finished flooring and light fixtures? Will you purchase in bulk for cost savings, or use a just-in-time (JIT) delivery system to minimize on-site storage? Each approach has pros and cons, impacting budget, logistics, and potential waste.

- Supply Chain Management: In today’s globalized world, supply chain disruptions are a real threat. Identifying critical materials and having backup suppliers, or even buffer stock for high-risk items, can save you from debilitating delays. Remember the lumber shortages during the pandemic? Planning for potential material scarcity is a skill in itself.

- Logistics and Storage: Where will materials be stored on site? How will they be protected from weather or theft? How will they be moved efficiently to the point of installation? A well-organized laydown area can dramatically improve workflow.

- Waste Reduction: Construction generates a significant amount of waste. Planning for material optimization, recycling, and responsible disposal not only has environmental benefits but can also reduce costs.

-

Equipment Resources:

- Selection and Availability: Do you need a tower crane, excavators, forklifts, specialized scaffolding? Selecting the right equipment for each task is crucial for efficiency and safety. More importantly, is it available when you need it? Heavy machinery often requires advance booking.

- Rental vs. Ownership: Should you rent a piece of equipment for a specific phase, or does it make more sense to own it if you foresee continuous use across multiple projects? This financial decision impacts your capital expenditure and operating costs.

- Maintenance and Downtime: Equipment breaks down. It’s a fact of life. Planning for routine maintenance and having contingency plans for unexpected breakdowns—like backup machinery or repair protocols—minimizes their impact on your schedule.

I recall a project where a critical batch of custom-fabricated steel beams for a unique architectural feature was held up in transit due to an unforeseen port strike. We had allocated the best structural team for that phase, and suddenly, they were sitting idle, still costing us money. Had we explored alternative fabrication sites or considered a more robust shipping contingency plan, the impact could have been mitigated. It was a tough lesson learned about the fragility of supply chains. Proper allocation and proactive management, truly, prevent these kinds of costly headaches.

6. Implement a Robust Communication Plan: The Lifeline of Collaboration

Imagine a symphony orchestra where each musician plays their own tune, at their own tempo, without ever looking at the conductor. Utter chaos, right? A construction project is no different. Without clear, consistent, and well-structured communication, even the most talented teams will struggle, leading to misunderstandings, duplicated efforts, missed deadlines, and ultimately, project failure. A robust communication plan isn’t just about sharing information; it’s about fostering genuine collaboration, building trust, and ensuring everyone — from the site laborer to the CEO — is informed, engaged, and aligned. It’s the veritable lifeline of your entire endeavor, and you simply can’t underestimate its power.

Why Communication Fails (and How to Fix It)

Communication often goes awry for predictable reasons: assumptions, siloed information, lack of clear channels, or simply overwhelming people with irrelevant data. A strong plan tackles these head-on by defining:

- Who Needs to Know What: Not everyone needs every detail. A project executive probably needs a high-level progress report, while a site supervisor needs granular daily instructions. Tailor the message to the audience.

- When They Need to Know It: Critical updates should be immediate. Routine progress reports can be weekly or bi-weekly. Knowing the right frequency prevents both information overload and critical knowledge gaps.

- How They’ll Receive It: This defines the channels. Is it an email, a project management software update, a phone call, a formal meeting, or a quick chat on site? Different messages require different mediums.

Key Components of Your Communication Strategy

-

Regular Meetings:

- Daily Huddles: Short, stand-up meetings on site each morning to discuss the day’s tasks, potential roadblocks, and safety concerns. Quick, efficient, and keeps everyone in sync.

- Weekly Progress Meetings: More formal, involving project managers, key supervisors, and perhaps client representatives. Review progress against the schedule, discuss emerging issues, and plan for the coming week.

- Monthly Executive Reviews: High-level updates for senior management and major stakeholders, focusing on overall project health, budget, major milestones, and strategic decisions.

- Specialized Meetings: Design reviews, safety briefings, subcontractor coordination meetings. Each has a specific purpose and audience.

-

Reporting Structures:

- Progress Reports: Concise summaries of work completed, upcoming activities, and any deviations from the plan (schedule or budget). Visual dashboards are incredibly effective here.

- Issue Logs/Risk Registers: Centralized documents to track problems, assign ownership, and monitor resolution. Transparency is key here.

- Change Order Logs: Formal documentation for all approved changes to scope, budget, or schedule. This prevents confusion and disputes.

-

Project Management Software: Tools like Procore, Aconex, Autodesk Construction Cloud, or even simpler platforms like Asana or Monday.com, provide centralized hubs for documents, schedules, task assignments, and communication logs. They create a single source of truth, reducing reliance on scattered emails and handwritten notes. This digital backbone is non-negotiable in modern construction, really it isn’t.

-

Open Door Policy & Feedback Loops: Encourage questions and concerns. Create an environment where team members feel comfortable raising issues without fear of reprisal. A well-placed question can prevent a major mistake. Soliciting feedback, both formal and informal, helps you continuously improve your communication strategy.

I once worked on a large public works project where a crucial design change wasn’t properly communicated down to the site crew for a critical section of retaining wall. The wall was built to the old spec, then had to be partially demolished and rebuilt, costing days and thousands. It was a stark, painful lesson in how a simple breakdown in the information flow can have disproportionate consequences. Open lines of communication don’t just help address issues promptly; they keep the entire project humming along smoothly, preventing those costly, morale-crushing reworks. It’s an investment in efficiency and team cohesion.

7. Plan for Contingencies: The Unexpected is Inevitable

No matter how meticulously you plan, how brilliantly you execute, or how thoroughly you account for every known variable, the universe, it seems, has a wicked sense of humor. Something unexpected will happen. A critical material shipment gets delayed by a freak storm. An underground utility line is discovered where no maps indicated it. A key piece of equipment breaks down. These aren’t failures of planning; they’re simply the realities of complex projects. This is precisely why planning for contingencies isn’t just smart; it’s absolutely vital. Think of it as having a well-stocked emergency kit for your journey, ready for those unexpected detours or breakdowns. It’s your safety net, allowing you to address challenges without derailing the entire project, and let me tell you, it’s a huge stress reliever.

The Art of Risk Management

Planning for contingencies is really the practical application of robust risk management. It’s a continuous process that involves several key steps:

-

Risk Identification: Brainstorming every conceivable thing that could go wrong. This involves your entire team, subcontractors, and even external experts. Categorize them: technical, external, organizational, project management, financial, environmental, safety, etc.

-

Risk Assessment: For each identified risk, evaluate its probability (how likely is it to occur?) and its impact (how severe would the consequences be if it did?). This helps you prioritize where to focus your mitigation efforts.

-

Risk Mitigation/Response Planning: This is where contingency planning truly comes into play. For high-probability, high-impact risks, you develop specific response plans. These could be:

- Avoid: Change the project plan to eliminate the risk entirely.

- Mitigate: Take steps to reduce the probability or impact of the risk (e.g., ordering critical materials from two suppliers).

- Transfer: Shift the risk to another party (e.g., through insurance or specific contract clauses with subcontractors).

- Accept: For low-probability, low-impact risks, you might simply accept the risk, but still have a small contingency in place if it occurs.

-

Risk Monitoring and Control: Risks aren’t static. New ones emerge, old ones disappear, and the probability or impact of existing risks can change. Regularly review your risk register, track trigger conditions, and update your response plans.

Budgeting for the Unknown: Contingency vs. Management Reserve

It’s important to differentiate between two types of reserves:

-

Contingency Reserve: This is typically a percentage of your estimated project cost, set aside to cover known-unknown risks – those you’ve identified and planned for, but whose occurrence is uncertain. This reserve is often controlled by the project manager and is allocated to specific work packages or control accounts within the budget. It’s for the ‘we know this might happen, so here’s a buffer.’

-

Management Reserve: This is a higher-level reserve, held by senior management or the project sponsor, to cover unknown-unknown risks – the truly unforeseen events that couldn’t have been predicted (e.g., a new government regulation, a major economic downturn affecting material costs). This reserve is only tapped with formal approval and usually involves a change to the project’s baseline budget.

For a general building project, a contingency budget of 10-15% of the total project cost is often a reasonable starting point, though it can vary significantly based on the project’s complexity, novelty, and inherent risks. A brownfield site, for instance, will demand a larger contingency for unforeseen ground conditions than a greenfield one. That just makes sense, doesn’t it?

I remember a time when a seemingly straightforward façade installation was delayed because the custom-fabricated glass panels failed a quality inspection on arrival. The supplier had promised a perfect batch, but reality bit us. Because we had a contingency budget and a pre-vetted alternative supplier, we were able to quickly order replacement panels, albeit at a premium, and adjust the schedule without completely derailing the entire project. Without that foresight, the delay and cost would have been devastating. Always, always plan for that unexpected rain on your parade. It’s not pessimistic; it’s simply realistic, and it makes you look like a hero when things go sideways.

8. Ensure Quality Control: The Hallmark of Excellence

In construction, quality isn’t just negotiable; it’s the very bedrock of your reputation, the longevity of your structure, and, crucially, the safety of its occupants. Cutting corners on quality is a short-sighted decision that inevitably leads to rework, costly repairs, legal liabilities, and a damaged brand. Therefore, ensuring stringent quality control measures throughout every phase of your project isn’t merely a nice-to-have; it’s a fundamental commitment to excellence. After all, a sturdy foundation doesn’t just hold up a building; it builds trust, and that’s invaluable. You want your work to stand the test of time, don’t you? Of course, you do.

Quality Assurance vs. Quality Control: A Key Distinction

It’s helpful to understand the difference between these two concepts:

- Quality Assurance (QA): This is about preventing defects. QA focuses on the processes and procedures used to ensure that quality standards are met. It’s proactive. Think of it as setting up the system to ensure things are done right from the beginning—training, standardized methods, documented procedures.

- Quality Control (QC): This is about detecting defects. QC involves the actual inspection and testing activities performed to verify that the project deliverables meet the defined quality standards. It’s reactive, in the sense that it identifies issues once they’ve occurred, but the goal is to catch them early. Daily site inspections, material testing, and checking installations are all QC activities.

Both QA and QC are essential. You need strong processes to prevent problems, and robust checks to catch any that slip through.

Implementing a Robust Quality Program

-

Define Clear Quality Standards: This means translating project specifications, local building codes, client expectations, and industry best practices into measurable quality criteria. What does a ‘smooth finish’ actually mean? What are the tolerances for concrete flatness? Clarity here prevents subjective interpretations and disputes.

-

Develop an Inspection and Test Plan (ITP): This document outlines what will be inspected, when (e.g., before concrete pour, during framing, after MEP rough-in), who is responsible for the inspection, and how it will be documented. It’s a roadmap for your QC activities.

-

Regular Inspections:

- Pre-installation Meetings: Before a critical new system or material is installed, gather the relevant teams (installer, supplier, QC manager) to review specifications, installation procedures, and quality checkpoints. This preventative step is invaluable.

- Hold Point Inspections: These are mandatory inspections that must occur and be approved before subsequent work can proceed. Pouring concrete over uninspected rebar, for instance, is a huge no-no.

- In-Process Inspections: Regular checks during ongoing work to catch issues early, before they become more expensive to fix.

- Final Inspections/Punch Lists: Comprehensive reviews at the end of a phase or project to identify any deficiencies that need to be rectified before handover.

-

Material Testing: Ensure all materials meet specified standards. This can involve lab testing of concrete compressive strength, steel tensile strength, or insulation R-value. Don’t just take the supplier’s word for it; verify.

-

Mock-ups: For critical or aesthetically sensitive elements, constructing a full-scale mock-up can be incredibly valuable. It allows the team and client to visualize the final product, test installation methods, and identify potential issues before mass production or installation begins.

-

Non-Conformance Reports (NCRs): When a quality deviation is found, it must be formally documented. An NCR describes the issue, its root cause, the proposed corrective action, and verification that the fix was successful. This creates an auditable trail and helps prevent recurrence.

I remember a particularly challenging high-rise project where the architectural façade involved complex custom panels. Despite detailed drawings, the initial installation was off by millimeters in a few critical areas. Our QC team caught it quickly during the in-process inspections, before too many panels had been fixed. The rework was still costly and frustrating, but imagine if we’d waited until the entire floor was done, or even worse, the entire building. The cost implications would have been astronomical. Quality isn’t just about avoiding problems; it’s about protecting your investment and upholding your integrity. It’s truly non-negotiable.

9. Obtain Necessary Permits and Approvals: Navigating the Regulatory Labyrinth

Before any actual construction can commence, you’ll undoubtedly encounter one of the most complex, time-consuming, and often frustrating aspects of project planning: navigating the regulatory landscape to obtain all necessary permits and approvals. This isn’t just a bureaucratic hurdle; it’s a critical legal requirement that ensures your project adheres to local codes, environmental regulations, safety standards, and zoning ordinances. Skipping this step, or even mismanaging it, can lead to devastating consequences: project halts, significant fines, legal action, and irreparable damage to your reputation. It’s a labyrinth, to be sure, but one you simply must traverse with meticulous care, you won’t get around it. Believe me.

The Multi-Layered World of Permits

The permits you need will vary wildly depending on your project’s location, size, and nature. Here’s a breakdown of what you might encounter:

-

Building Permits: These are fundamental, ensuring your design and construction methods comply with local building codes, which cover structural integrity, fire safety, accessibility, and general construction standards.

-

Zoning Permits/Approvals: Your project must align with local zoning laws, dictating land use, building height, setbacks (distance from property lines), parking requirements, and allowable floor area. Variances or rezonings can be lengthy processes, sometimes requiring public hearings.

-

Environmental Permits: Depending on your site, you might need permits for stormwater discharge, wetland impacts, air quality, hazardous material handling, or even noise pollution. Environmental Impact Assessments (EIAs) often precede these permits.

-

Utility Permits: Connecting to municipal water, sewer, gas, and electrical grids typically requires separate permits and coordination with utility providers. This also includes permits for any work within public rights-of-way.

-

Fire Safety Permits: Often distinct from general building permits, these ensure your fire suppression systems, alarms, and emergency exits meet stringent fire codes.

-

Demolition Permits: If your project involves tearing down existing structures, you’ll need specific permits for demolition, often including plans for debris disposal and environmental precautions.

-

Historic Preservation/Conservation Area Approvals: If your site is in a designated historic district or involves a heritage building, expect additional layers of review and approval from preservation boards.

The Permit Application Process: A Marathon, Not a Sprint

The process typically involves:

- Pre-Application Meetings: Engaging with regulatory officials early can help clarify requirements, identify potential roadblocks, and streamline the application process.

- Detailed Submittals: Preparing comprehensive architectural and engineering drawings, structural calculations, site plans, energy efficiency reports, and environmental studies. The devil is truly in the details here.

- Review and Comment Cycles: Your submittals will be reviewed by various departments (planning, building, fire, public works). Expect rounds of comments and revisions. This can be time-consuming, and communication with reviewers is crucial.

- Fees and Charges: Permit applications often come with substantial fees, based on project value, size, or complexity.

- Inspections: Even after permits are issued, various stages of construction will require mandatory inspections to ensure compliance before you can proceed.

One time, we had a project for a multi-family residential building, and everything seemed ready. Plans were approved, permits in hand, foundations poured. Then, during a routine utility connection, the city informed us that an obscure, recently enacted bylaw, passed after our initial application, now required a different storm drain connection for buildings of our new (recently re-categorized) size. It meant redesigning the drainage, digging up part of the foundation, and reapplying for a specific utility permit. The delay and cost were significant, and it was a painful reminder that the regulatory goalposts can sometimes shift, even mid-game. Having a dedicated permit manager or consultant who lives and breathes this stuff can be an absolute lifesaver. You want someone who knows the system, knows the people, and can foresee these kinds of potential issues. It’s an investment that pays off immensely.

10. Monitor Progress and Adjust as Needed: The Art of Dynamic Management

Once the foundational planning is complete, permits are in hand, and construction is underway, the project isn’t on autopilot. Far from it. This is where dynamic project management truly shines. Continual vigilance, regular progress monitoring, and a willingness to make timely adjustments are absolutely critical to staying on course. Think of yourself as the captain of a ship, constantly checking the compass, the weather, and the speed, ready to correct your heading or hoist a different sail at a moment’s notice. You can’t just set a course and walk away; you must actively steer it. And sometimes, you really have to lean into those adjustments.

Key Performance Indicators (KPIs) for Tracking Success

Effective monitoring relies on tracking Key Performance Indicators. These are measurable values that demonstrate how effectively you’re achieving your project objectives. In construction, common KPIs include:

- Schedule Performance Index (SPI): Measures how efficiently you’re progressing against your schedule. An SPI > 1 means you’re ahead; < 1 means you’re behind.

- Cost Performance Index (CPI): Measures the cost efficiency of your work. A CPI > 1 means you’re under budget; < 1 means you’re over budget.

- Earned Value Management (EVM): A powerful project management technique that integrates scope, schedule, and cost performance to give you a holistic view of project health.

- Quality Metrics: Number of defects, rework rate, compliance with specifications.

- Safety Incidents: Lost time injuries, near misses, compliance with safety protocols.

- Resource Utilization: How efficiently are your labor, materials, and equipment being used?

Reporting Mechanisms for Informed Decision-Making

Transparent and timely reporting is essential to keep all stakeholders informed and enable quick decision-making:

- Dashboards: Visual, real-time representations of key KPIs, providing an at-a-glance overview of project status. These are great for quick updates to executives.

- Status Reports: Regular (weekly, bi-weekly) written reports detailing progress, issues, risks, and upcoming activities. These are more detailed than dashboards and provide context.

- Forecasts: Projections of future costs and completion dates, based on current performance and anticipated changes. This helps with proactive planning.

The Necessity of Change Management

One of the most crucial aspects of dynamic management is a robust change management process. Changes—whether from client requests, unforeseen site conditions, or new regulations—are inevitable. Without a formal process, they can quickly lead to chaos and uncontrolled scope creep. Your process should include:

- Change Request: Anyone can submit a formal request for a change.

- Impact Assessment: The project team evaluates the impact of the proposed change on scope, schedule, budget, quality, and resources.

- Approval: Depending on the impact, the change might need approval from the project manager, the client, or even the project sponsor.

- Implementation: Once approved, the change is incorporated into the project plan, and all baselines (scope, schedule, budget) are formally updated.

- Communication: All affected stakeholders are informed of the change.

I vividly remember a residential tower project where the client requested a major redesign of the penthouse units midway through structural framing. It was a huge change. Our change management process kicked in: we analyzed the structural implications, the impact on MEP systems, the new material procurement, and the schedule delays. The client understood the implications and approved the revised budget and timeline. If we hadn’t had that formal process, if we’d just ‘squeezed it in,’ the project would have become a financial and scheduling nightmare. Continuous monitoring means you’re not just reacting, but proactively shaping the project’s trajectory. It means you’re always in control, even when the unexpected rears its head. It truly distinguishes a well-run project from a chaotic one.

By diligently following these comprehensive steps, from defining the very essence of your project to continuously monitoring its pulse, you can confidently navigate the inherent complexities of building project planning. Remember, a well-prepared, dynamically managed plan isn’t just the foundation of a successful construction project; it’s your guarantee of resilience, efficiency, and ultimate triumph. It’s the difference between merely building a structure and constructing a lasting legacy.

References

- Project Planning in Construction: Tools, Phases, and Tips. Mastt. (mastt.com)

- How to Plan a Construction Project for Consistent Results. CMiC. (cmicglobal.com)

- Construction Planning Techniques and Best Practices. RIB Software. (rib-software.com)

- How to Plan a Successful Building Project? A Detailed Guide. Arlis. (arlis.org.uk)

Be the first to comment