Bringing Brilliance to the Built Environment: A Deep Dive into Data-Driven Predictive Control for Existing Buildings

In our rapidly evolving world, where energy conservation isn’t just a buzzword but a global imperative, smart buildings have truly emerged as a shining beacon of efficiency. It’s not merely about slapping some fancy tech onto a structure; no, it’s about fundamentally rethinking how our built environments operate. By cleverly harnessing sophisticated cyber-physical systems and advanced data-driven predictive control strategies, these intelligent structures don’t just optimize energy usage, they also profoundly enhance the comfort, productivity, and overall well-being of their occupants. And frankly, that’s a game-changer.

Think about it: most of the buildings we work and live in today weren’t designed with today’s energy challenges in mind. They’re often energy guzzlers, running on outdated systems that operate reactively rather than proactively. The rain lashes against the windows, the wind howls like a banshee, and yet the HVAC system might still be running as if it’s a calm summer’s day. That’s a lot of wasted energy, a lot of unnecessary expense, and a hefty carbon footprint. But what if we could teach these old dogs new tricks? What if we could imbue them with an almost intuitive understanding of their own energy needs and the dynamics of their environment? That’s precisely where data-driven predictive control steps in, offering a compelling path to transforming existing infrastructure into responsive, sustainable powerhouses.

Successful low-energy building design hinges on careful planning. Focus360 Energy can help.

Unpacking Cyber-Physical Systems in the Smart Building Ecosystem

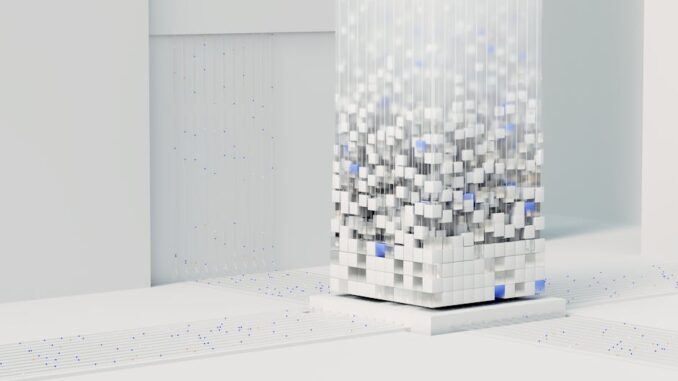

Before we dive too deep into the ‘how-to,’ it’s crucial we get a firm grasp on the foundational technology: Cyber-Physical Systems, or CPS. At its core, CPS represents a profound integration of computation, networking, and physical processes. You can imagine it as the building’s brain, nervous system, and muscles all working in perfect harmony, continuously. In the world of smart buildings, CPS isn’t just a concept; it’s the very fabric that allows a structure to become ‘smart.’

It involves embedding a rich tapestry of sensors, actuators, and sophisticated control systems directly into the building’s very infrastructure. These aren’t just isolated components; they form an interconnected web, constantly monitoring and managing an incredible array of operations. We’re talking about everything from the mundane to the mission-critical: the heating, ventilation, and air conditioning (HVAC) systems, of course, but also lighting, security cameras, access control, fire safety, elevator operations, even waste management. This deep, pervasive integration allows for real-time data collection and analysis at a scale previously unimaginable, which in turn enables dynamic, intelligent adjustments to building systems.

Consider the feedback loop: sensors detect changes in the physical environment—perhaps an increase in occupancy, a sudden drop in outdoor temperature, or even a rise in CO2 levels in a meeting room. This raw data streams through the network to computational units, often an edge device or a centralized cloud platform, where it undergoes analysis. Algorithms process this information, comparing it against historical patterns, predictive models, and desired operational parameters. Based on this analysis, the system then dispatches commands to actuators—valves open or close, fan speeds increase or decrease, lights dim or brighten, all with precision and purpose. It’s a continuous, self-optimizing dance, much like a living organism adapting to its surroundings.

Where traditional Building Management Systems (BMS) often act as static taskmasters, executing predefined rules, a CPS-enabled smart building is more like a highly intelligent, adaptive entity. It sees, it learns, and it acts, all in service of efficiency and comfort. This isn’t just about turning things on and off; it’s about making nuanced, informed decisions moment by moment, which really makes all the difference.

The Power of Data-Driven Predictive Control Strategies

Now, let’s talk about the ‘smart’ part of smart buildings: data-driven predictive control. This is where the magic truly happens, transforming raw data into actionable intelligence. Unlike those traditional control methods, which, bless their hearts, rely on static, predefined rules (like ‘turn on the AC if it’s above 75 degrees’), these advanced strategies harness historical and real-time data to forecast future building performance. It’s like having a crystal ball, but one powered by algorithms and accurate data points.

Imagine a system that knows, with remarkable accuracy, that next Tuesday will be unseasonably warm, a flurry of meetings will pack the third floor, and electricity prices will peak mid-afternoon. Armed with this foresight, the system can then intelligently pre-cool certain zones, adjust ventilation schedules, or even shift energy consumption to off-peak hours before any of these events actually happen. This proactive approach leads to vastly more efficient energy management, a noticeable reduction in utility bills, and a significantly more comfortable environment for everyone inside. You won’t find yourself sweating it out on a Tuesday afternoon, waiting for the AC to finally kick in.

These predictive models don’t just look at internal data, either. They pull in external factors like hyper-local weather forecasts, grid electricity prices, even public holiday schedules. They can identify subtle patterns that human operators might miss, uncovering opportunities for savings and optimization. For instance, a model might detect that a particular corner office always overheats on sunny afternoons, even in winter, and proactively adjust the solar blinds or localized heating/cooling to compensate before anyone even feels uncomfortable. It’s about anticipation, not reaction, and that’s a fundamental shift in how buildings operate.

Retrofitting for Resilience: Implementing Data-Driven Predictive Control in Existing Buildings

So, you’re convinced. You see the immense potential. But how do you take a building that’s perhaps decades old, a venerable structure with its own quirks and legacy systems, and imbue it with this cutting-edge intelligence? It’s a journey, to be sure, but a highly rewarding one. Upgrading existing buildings with data-driven predictive control strategies involves a structured, multi-step approach, and honestly, you’ll find it more manageable than you might think.

Step 1: The Grand Tour – Assessment of Current Systems

Before you can leap forward, you really need to understand where you’re starting from. This initial assessment is absolutely critical. You’ll begin by thoroughly evaluating the existing Building Management Systems (BMS), if one exists, and all related infrastructure. What kind of HVAC system do you have? Are the controls pneumatic, analog, or already somewhat digital? What about lighting controls? How old is the wiring? Identifying areas where predictive control can be integrated, or where it’s desperately needed, is key.

This isn’t just a technical audit, though. You’ll also want to conduct an energy audit to benchmark current consumption and pinpoint energy ‘hogs.’ Are certain zones always too hot or too cold? Are lights left on overnight in unoccupied areas? Talk to building occupants and facility managers. Their lived experience provides invaluable qualitative data that numbers alone can’t capture. Understanding the building’s operational profile—its peak occupancy times, its unique climate challenges, its existing pain points—sets the stage for a truly tailored solution. Sometimes you’ll uncover quick wins right here, even before you’ve fully deployed any new tech. Think of it as mapping your treasure before you start digging.

Step 2: Wiring Up – Establishing Data Collection Infrastructure

Once you know what you’re working with, it’s time to equip your building with the senses it needs. This means installing a robust data collection infrastructure. Think about a dense network of smart sensors and meters. These devices are the eyes and ears of your smart building, tirelessly gathering granular data on everything imaginable: occupancy levels, temperature, humidity, CO2 concentration, light levels, air quality, water flow, and, crucially, real-time energy consumption at various points throughout the building. You’ll also need smart meters, perhaps at the utility entry point and sub-meters for specific systems or floors.

The choice of sensors and their placement is vital. You’re not just throwing darts at a board; you’re strategically positioning these devices to capture the most relevant information without creating ‘blind spots.’ Consider integrating existing sensors if they’re compatible, but be prepared for new installations. Network connectivity is another big piece of this puzzle. Will you use wired Ethernet, or are wireless IoT protocols like LoRaWAN, Zigbee, or Wi-Fi better suited for your existing infrastructure? Compatibility with existing protocols like BACnet or Modbus will streamline integration, but sometimes a good IoT gateway can bridge the divide between older and newer systems. Data quality, by the way, is paramount here; garbage in, garbage out, as the saying goes.

Step 3: Making Sense of the Swirl – Data Integration and Analysis

With data now flowing in, the next step is to make sense of it all. This involves utilizing specialized software platforms to aggregate, cleanse, and analyze the collected data. We’re talking about sophisticated Building Management Systems (BMS), Energy Management Information Systems (EMIS), or dedicated cloud-based analytics platforms. These systems act as the central nervous system, pulling in data from disparate sources, normalizing it, and presenting it in a coherent, understandable format.

This stage often involves overcoming the ‘data silo’ challenge—where different building systems (HVAC, lighting, security) operate independently with their own data stores. Robust APIs and adherence to interoperability standards are crucial here. The goal is to create a single pane of glass, a comprehensive dashboard, where facility managers can visualize building performance, identify anomalies, and track key metrics. Think about seeing real-time energy consumption next to occupancy data and outside temperature, all on one screen. This integrated view provides invaluable insights into building performance, highlighting areas of inefficiency or opportunities for optimization that were previously invisible. It’s about turning raw numbers into compelling narratives.

Step 4: The Crystal Ball – Model Development

This is where the ‘predictive’ aspect truly takes shape. You’ll need to develop predictive models that simulate building behavior under a vast array of conditions. These aren’t just simple formulas; they are often complex machine learning algorithms—regression models, neural networks, or even more advanced reinforcement learning agents. They’re trained on the historical data you’ve meticulously collected, learning the intricate relationships between environmental factors, occupancy patterns, and energy consumption. For instance, a model might learn that on sunny Tuesdays with more than 50% office occupancy, cooling loads in the west wing consistently spike between 1 PM and 3 PM.

The process involves data cleaning (removing erroneous readings, filling gaps), feature engineering (creating new variables from existing data that improve model performance), training the model, and then rigorously validating it against unseen data. The more data and the higher its quality, the more accurate and robust your models will become. These models essentially create a ‘digital twin’ of your building, a virtual replica that can forecast future scenarios, test different control strategies, and even identify potential equipment failures before they occur. It’s an incredibly powerful tool for informed decision-making.

Step 5: Taking the Reins – Control Strategy Implementation

With your predictive models humming along, the next logical step is to deploy algorithms that translate these predictions into actual adjustments within the building systems. This means integrating the intelligence from your models directly into your control logic. The algorithms will dynamically adjust HVAC setpoints, lighting levels, fan speeds, chiller operation, and more, all based on the forecasts generated by your predictive models.

For instance, if the model predicts a significant cooling demand due to an upcoming heatwave, the system might initiate pre-cooling during off-peak hours when electricity is cheaper. If a particular zone is predicted to be unoccupied for several hours, the system might automatically reduce ventilation and lighting there, then ramp them back up just before expected arrival. The key is to optimize energy usage without compromising occupant comfort. This often involves a delicate balancing act, and the best systems incorporate feedback loops from occupants (e.g., through mobile apps) to fine-tune comfort settings. Safety protocols and reliable fallback mechanisms are also paramount; you wouldn’t want the system to accidentally overheat a critical server room, for instance.

Step 6: The Long Game – Continuous Monitoring and Refinement

Implementing predictive control isn’t a ‘set it and forget it’ kind of deal. Buildings are dynamic environments, constantly changing. Occupancy patterns shift, equipment ages, even the local climate evolves. Therefore, continuous monitoring and refinement are absolutely essential for long-term success. You’ll need to regularly monitor system performance against key metrics: actual energy savings, occupant comfort levels (perhaps through surveys or internal temperature logs), and system uptime.

The predictive models themselves will need periodic retraining and refinement as new data becomes available or as building operations change. This adaptive learning ensures that the system remains relevant and optimal over time. Facility managers will play a crucial role in overseeing the system, providing valuable human insight, and making adjustments based on real-world feedback. Think of it as a living, breathing system that evolves with your building. This iterative process, this constant cycle of learning and optimizing, is what truly locks in the long-term benefits and ensures that your smart building remains brilliant, year after year.

Real-World Triumphs: Case Studies in Smart Building Transformation

While the theoretical benefits are compelling, seeing these strategies in action truly underscores their power. Several real-world applications beautifully demonstrate the effectiveness of data-driven predictive control in enhancing energy efficiency and beyond:

-

45 Broadway, Manhattan: A Glimpse into AI-Driven HVAC Optimization. Imagine a towering 32-story office building right in the heart of Manhattan. In 2019, this building, 45 Broadway, was facing the perennial challenge of managing HVAC costs in a dynamic urban environment. They adopted an AI-driven system from BrainBox AI, a move that really paid off. This wasn’t just a minor tweak; the system significantly reduced HVAC-related energy consumption by an impressive 15.8%. Think about that for a moment: nearly a sixth of their HVAC energy disappeared. The financial impact was substantial too, saving them over $42,000 annually, which, in the context of commercial real estate, is nothing to sneeze at. And for the environmentally conscious, it also mitigated a substantial 37 metric tons of CO₂ equivalent. This wasn’t some hypothetical lab experiment; it was a concrete, measurable win in a high-stakes setting, proving that smart tech can indeed make a massive difference. You can read more about it over at time.com, it’s a fascinating read.

-

Commercial and Institutional Buildings in Canada: A Deep Dive into Model-Based Control. Across the border, a comprehensive study investigated the impact of three data-driven model-based control strategies implemented in a range of commercial and institutional buildings across Canada. These strategies focused on critical areas like chiller sequencing, leveraging free cooling (using cool outside air instead of mechanical refrigeration), and optimizing supply air temperature reset. The results were quite telling. Implementing these smart measures resulted in a notable 12% reduction in overall cooling energy consumption. What’s even more impressive is that the electrical energy specifically used by the cooling system plummeted by a remarkable 33%. This clearly demonstrates that even targeted, well-implemented predictive strategies can yield substantial energy and cost savings, without necessarily overhauling the entire building from scratch. It just goes to show how much low-hanging fruit there really is when you apply intelligence to operations. (mdpi.com)

-

A University Campus in Europe: Learning and Adapting to Diverse Usage. Let’s conjure up another scenario. A large university campus, bustling with students and faculty, features a variety of building types: lecture halls, research labs, administrative offices, and dormitories. Each building has wildly different occupancy patterns and energy demands. The facilities team implemented a predictive control system that integrated with the existing BMS across several key buildings. The system learned the rhythm of the campus—when classes let out, when labs were active, even the varying schedules of student residents. It proactively adjusted ventilation and heating in lecture halls, pre-cooled server rooms during anticipated peaks in compute usage, and even dimmed lighting in common areas during quieter periods. The result? A measurable 10% reduction in overall electricity consumption and a significant improvement in occupant comfort, as students reported fewer instances of rooms being either too stuffy or too chilly. It truly showcased the adaptability of these systems to complex, diverse environments.

Navigating the Roadblocks: Challenges and Key Considerations

While the siren song of energy efficiency and enhanced comfort is incredibly alluring, implementing data-driven predictive control strategies in existing buildings isn’t without its speed bumps. You’ll encounter a few hurdles, and it’s always best to be prepared for them.

Data Privacy and Security: The Digital Fortress

In an age where data breaches are unfortunately commonplace, ensuring the security and privacy of collected data is absolutely paramount. Smart buildings gather an immense amount of sensitive information, from occupancy patterns that could reveal individual movements to energy consumption data that might hint at internal processes. What if this data falls into the wrong hands? The implications are serious, impacting both occupant trust and corporate reputation.

You’ll need robust cybersecurity measures: end-to-end encryption for data in transit and at rest, stringent access controls, anonymization techniques for personal data, and regular security audits. Compliance with data protection regulations like GDPR or CCPA isn’t just a suggestion; it’s a legal obligation. Beyond the technical aspects, clear communication with occupants about what data is being collected, why it’s being collected, and how it’s being protected can go a long way in building trust. After all, nobody wants to feel like Big Brother is constantly watching their thermostat.

Integration with Existing Systems: The Legacy Maze

This is often the biggest beast to tame. Many older buildings are a patchwork quilt of legacy systems, sometimes proprietary, often lacking modern communication interfaces. You might find a 30-year-old pneumatic control system next to a newer, but still isolated, digital lighting setup. Getting these disparate systems to ‘talk’ to each other, to share data, and to respond to centralized commands can be a significant undertaking. It’s like trying to get a rotary phone to FaceTime with an iPhone; it just won’t happen without some serious middleware.

Expect challenges like incompatible protocols, lack of accessible APIs, vendor lock-in, and even incomplete documentation for older systems. Strategies to overcome this include implementing robust communication gateways, utilizing standardized protocols where possible (like BACnet IP or Modbus TCP), and being prepared for phased upgrades of older components. Sometimes, it might even mean completely replacing certain antiquated systems, which, while costly, might be the only viable path to achieving true integration and control. Patience, and a good system integrator, are virtues here.

Initial Investment: Weighing the Upfront Costs

The benefits are long-term, yes, but the upfront cost of installing new sensors, upgrading network infrastructure, procuring software licenses, and developing sophisticated models can be substantial. It’s not a trivial investment, and for many building owners or managers, that initial sticker shock can be a deterrent. You’re looking at costs for hardware, software, engineering hours, and staff training. It’s a lot to consider.

However, it’s crucial to view this not as an expense, but as an investment with a clear return. Conduct a thorough Return on Investment (ROI) analysis, factoring in projected energy savings, reduced maintenance costs (due to predictive maintenance), increased property value, and even improved occupant productivity. Explore financing options like Property Assessed Clean Energy (PACE) programs or Energy Service Agreements (ESAs), where a third party covers the upfront cost in exchange for a share of the energy savings. Sometimes, government grants or incentives for sustainable building upgrades can also help offset these initial costs. It’s about building a compelling business case, not just dreaming of a greener future.

The Talent Gap: Who’s Running the Show?

Implementing and managing these sophisticated systems requires a specific blend of expertise. You can’t just hand it off to your existing maintenance crew without proper training. You’ll need professionals who understand building mechanics, controls engineering, IT networking, and increasingly, data science and machine learning. Finding individuals with this multidisciplinary skill set can be tough, creating a potential talent gap.

Investing in training for existing staff is one approach, equipping them with the new skills needed to operate and troubleshoot these advanced systems. Alternatively, partnering with specialized smart building service providers or leveraging cloud-based platforms that offer managed services can help bridge this gap. The shift from reactive maintenance to data-driven proactive management demands a different kind of workforce, and preparing for that is an important consideration.

Occupant Acceptance: The Human Element

Ultimately, buildings are for people. Any technological upgrade, especially one that directly impacts environmental controls, needs to consider the occupants. Changes in temperature setpoints, lighting schedules, or ventilation rates, even if optimized for energy, can lead to discomfort or dissatisfaction if not managed well. Humans, we’re creatures of habit, aren’t we?

It’s important to engage occupants early in the process, communicating the benefits of the new system (e.g., ‘fewer cold spots,’ ‘better air quality,’ ‘our commitment to sustainability’). Providing feedback mechanisms, like simple mobile apps where occupants can report comfort levels, allows for fine-tuning and fosters a sense of involvement rather than imposition. A smart building should enhance, not detract from, the human experience within its walls.

The Path Forward: A Smart, Sustainable Future

Integrating data-driven predictive control strategies into existing buildings truly offers a promising, incredibly exciting path to enhanced energy efficiency. By leveraging the seamless capabilities of cyber-physical systems, buildings gain the ability to adapt intelligently to real-time conditions, dynamically optimize energy usage, and consistently provide a comfortable, productive environment for everyone who walks through their doors. We’re talking about buildings that learn, that anticipate, that actually care about their occupants and the planet.

While the challenges I’ve outlined—data security, integration complexities, initial investments, the talent crunch, and even occupant acceptance—are certainly real, they are far from insurmountable. The potential benefits, both financially through significant cost savings and environmentally through a reduced carbon footprint, make this endeavor incredibly worthwhile for any building owner or manager committed to sustainability, operational excellence, and long-term value creation. The future of our built environment isn’t just about constructing new smart buildings; it’s about making every building smarter. And that, I’d say, is a mission worth pursuing, don’t you think?

This article highlights the transformative potential of predictive control in existing buildings. How do you foresee the integration of real-time energy grid data influencing these control strategies, especially concerning demand response and grid stabilization efforts?

That’s a great point! Integrating real-time energy grid data is key. Imagine buildings proactively adjusting consumption based on grid stress signals or pricing fluctuations. This could significantly enhance demand response programs, contributing to grid stabilization and potentially unlocking cost savings. It requires robust communication protocols and predictive algorithms that can translate grid data into actionable building controls.

Editor: FocusNews.Uk

Thank you to our Sponsor Focus 360 Energy

The mention of data privacy and security is critical. How can blockchain technology enhance the transparency and security of the data collected by cyber-physical systems in smart buildings, ensuring user trust and regulatory compliance?

That’s a fantastic question! Exploring blockchain’s potential for enhanced data security is vital. Its decentralized, immutable nature could revolutionize how building data is managed, fostering greater transparency and trust. Imagine verifiable audit trails for energy usage and environmental data, leading to increased accountability. It would be interesting to see how it can be implemented cost effectively. What are your thoughts?

Editor: FocusNews.Uk

Thank you to our Sponsor Focus 360 Energy

Cyber-physical systems as the building’s brain? Fascinating! But what about the potential for these “brains” to start developing quirks? Could we end up with buildings that are *too* smart for their own good, making energy-saving decisions that prioritize efficiency over, say, that perfect afternoon sunbeam?

That’s a brilliant point! The potential for “quirks” in hyper-intelligent systems is something we need to address. Perhaps a user override function, allowing occupants to adjust settings (like enjoying that afternoon sunbeam!) could strike the right balance between automation and personal preference. What do you think about the idea of having a blend of automated and manual controls?

Editor: FocusNews.Uk

Thank you to our Sponsor Focus 360 Energy

The discussion around legacy system integration is crucial. Beyond standardized protocols, what role could open-source platforms play in creating a more unified ecosystem, allowing for easier data sharing and control across diverse building systems?

That’s an insightful point about open-source platforms! Leveraging open-source could definitely foster a more collaborative and adaptable environment for integrating diverse legacy systems. It could lower costs, encourage innovation through community contributions, and avoid vendor lock-in. How do we encourage wider adoption in the building automation sector?

Editor: FocusNews.Uk

Thank you to our Sponsor Focus 360 Energy

Cyber-physical systems as the building’s brain? That’s a cool analogy! But could we teach buildings to appreciate disco? Imagine the energy savings from a building deciding it only needs flashing lights and funky music on Saturday nights!