Abstract

Ductwork systems are integral components of modern Heating, Ventilation, and Air Conditioning (HVAC) systems, facilitating the distribution of conditioned air throughout buildings. This research report presents a comprehensive review of ductwork systems, exploring their evolution, diverse materials and designs, performance characteristics, and ongoing challenges. The study delves into advanced modeling techniques used for ductwork design and optimization, focusing on computational fluid dynamics (CFD) simulations and their role in predicting airflow patterns, pressure losses, and thermal behavior. Furthermore, it investigates novel materials and fabrication methods that enhance energy efficiency, reduce air leakage, and improve indoor air quality. The report also addresses critical issues such as ductwork leakage, thermal losses, and the impact of these factors on overall HVAC system performance. Finally, the report analyzes the economic and environmental implications of ductwork system improvements, considering life-cycle costs and sustainability factors. This research aims to provide a valuable resource for HVAC professionals, researchers, and policymakers involved in the design, installation, and maintenance of efficient and sustainable ductwork systems.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

1. Introduction

Ductwork systems have undergone significant advancements since their inception, evolving from simple air passages to sophisticated networks designed to optimize airflow, minimize energy consumption, and maintain indoor air quality. The increasing demand for energy-efficient buildings has driven innovation in ductwork materials, design methodologies, and installation techniques. Contemporary ductwork systems must address a complex set of requirements, including minimizing air leakage, reducing thermal losses, ensuring proper airflow distribution, and mitigating noise generation. These demands necessitate a multidisciplinary approach, integrating principles of fluid mechanics, heat transfer, materials science, and acoustics.

Historically, ductwork systems were primarily constructed from galvanized steel, which provided durability and structural integrity. However, galvanized steel is susceptible to corrosion, particularly in humid environments. Moreover, the installation of galvanized steel ductwork often requires specialized tools and skilled labor, increasing construction costs. In recent years, alternative materials such as fiberglass duct board, flexible ducts, and pre-insulated ductwork have gained popularity due to their ease of installation, lower cost, and improved thermal performance.

The design of ductwork systems is a critical aspect of HVAC engineering, influencing both the performance and energy efficiency of the entire system. Traditional ductwork design methods rely on simplified calculations and empirical correlations to estimate airflow rates, pressure drops, and duct sizes. However, these methods often fail to accurately capture the complex flow phenomena that occur in real-world ductwork systems. Advanced modeling techniques, such as Computational Fluid Dynamics (CFD), offer a more sophisticated approach to ductwork design, enabling engineers to simulate airflow patterns, temperature distributions, and pollutant dispersion with high accuracy. CFD simulations can be used to optimize ductwork geometry, identify potential problem areas (e.g., regions of high pressure drop or stagnant flow), and evaluate the effectiveness of various design modifications.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

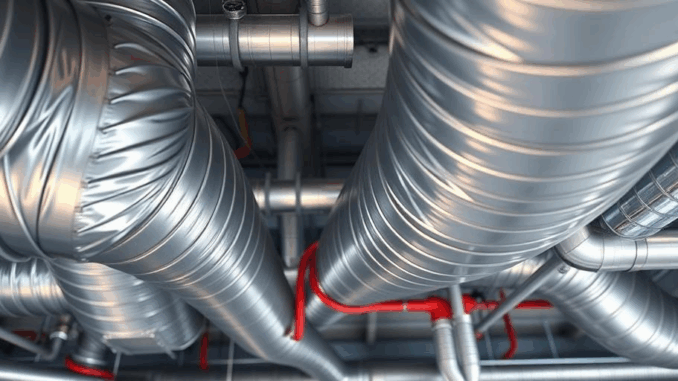

2. Ductwork Materials and Fabrication Techniques

Ductwork materials play a crucial role in determining the performance, durability, and cost-effectiveness of HVAC systems. The selection of appropriate materials must consider factors such as thermal conductivity, air leakage resistance, fire resistance, and environmental impact. This section provides a detailed overview of commonly used ductwork materials and emerging fabrication techniques.

2.1. Galvanized Steel

Galvanized steel remains a widely used material for ductwork construction due to its high strength, durability, and relatively low cost. The galvanization process involves coating the steel with a layer of zinc, which provides corrosion protection. However, galvanized steel is susceptible to corrosion in highly humid or corrosive environments. Furthermore, the installation of galvanized steel ductwork typically requires specialized tools and skilled labor, which can increase installation costs.

2.2. Aluminum

Aluminum offers excellent corrosion resistance and is lighter than steel, making it an attractive alternative for ductwork construction, especially in corrosive environments such as coastal regions or industrial facilities. Aluminum ductwork is also easier to fabricate and install compared to galvanized steel. However, aluminum is more expensive than steel and has a lower strength-to-weight ratio, which may limit its use in certain applications.

2.3. Fiberglass Duct Board

Fiberglass duct board consists of rigid fiberglass insulation faced with an air-impermeable coating. It offers excellent thermal insulation and sound attenuation properties, reducing heat loss and noise transmission. Fiberglass duct board is lightweight and easy to fabricate, making it a popular choice for residential and light commercial applications. However, fiberglass duct board is susceptible to damage from moisture and physical impact. Concerns about indoor air quality related to fiberglass particle release have also limited its use in some applications, though modern products have mitigated those concerns.

2.4. Flexible Ducts

Flexible ducts are typically constructed from a wire helix covered with a flexible material such as polyethylene or polyester. They offer ease of installation and can be used to connect ductwork to diffusers and registers in hard-to-reach areas. However, flexible ducts have a higher pressure drop compared to rigid ducts and are more prone to air leakage. Furthermore, flexible ducts can sag or kink if not properly supported, which can restrict airflow. The use of excessive flexible ducting should always be avoided to minimize system inefficiency.

2.5. Pre-insulated Ductwork

Pre-insulated ductwork combines the structural integrity of metal ductwork with the thermal performance of insulation. It typically consists of a galvanized steel or aluminum duct section with an outer layer of insulation, such as mineral wool or fiberglass. Pre-insulated ductwork offers excellent thermal performance, reduced air leakage, and simplified installation. However, it is more expensive than traditional ductwork systems.

2.6. Fabric Ductwork

Fabric ductwork, also known as textile ductwork, is made from engineered fabrics that are designed to distribute air evenly throughout a space. Fabric ductwork is lightweight, easy to install, and can be customized to match the aesthetic requirements of the building. It offers excellent air diffusion and is resistant to condensation. However, fabric ductwork requires regular cleaning to maintain its performance and appearance. Its application is typically limited to open ceiling environments.

2.7. Emerging Materials and Fabrication Techniques

Ongoing research is exploring new materials and fabrication techniques for ductwork systems. These include composite materials, such as fiber-reinforced polymers, which offer high strength-to-weight ratios and excellent corrosion resistance. Additive manufacturing (3D printing) is also being investigated as a potential method for fabricating complex ductwork geometries with customized performance characteristics. The use of bio-based materials, such as cellulose-based insulation, is also gaining attention due to their environmental benefits.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

3. Ductwork Design and Modeling

The design of ductwork systems is a complex engineering challenge that requires careful consideration of factors such as airflow rates, pressure drops, duct sizes, and noise generation. Traditional ductwork design methods rely on simplified calculations and empirical correlations, which may not accurately capture the complex flow phenomena that occur in real-world ductwork systems. Advanced modeling techniques, such as CFD, offer a more sophisticated approach to ductwork design, enabling engineers to simulate airflow patterns, temperature distributions, and pollutant dispersion with high accuracy.

3.1. Traditional Ductwork Design Methods

Traditional ductwork design methods, such as the equal friction method and the velocity reduction method, are based on simplified assumptions about airflow and pressure drop. These methods rely on empirical correlations to estimate the pressure drop in duct sections and fittings. While these methods are relatively simple to apply, they may not accurately predict the performance of complex ductwork systems. Furthermore, they often fail to account for factors such as air leakage and thermal losses, which can significantly impact the overall efficiency of the HVAC system. The accuracy of these methods is heavily reliant on the experience and judgment of the engineer.

3.2. Computational Fluid Dynamics (CFD)

CFD is a powerful numerical technique that can be used to simulate fluid flow, heat transfer, and mass transfer in complex geometries. CFD simulations can provide detailed information about airflow patterns, temperature distributions, and pollutant dispersion in ductwork systems. This information can be used to optimize ductwork geometry, identify potential problem areas (e.g., regions of high pressure drop or stagnant flow), and evaluate the effectiveness of various design modifications. CFD simulations are widely used in the design of high-performance ductwork systems, such as those used in hospitals, laboratories, and cleanrooms.

The accuracy of CFD simulations depends on several factors, including the quality of the computational mesh, the accuracy of the turbulence model, and the proper specification of boundary conditions. Validating CFD simulations with experimental data is essential to ensure their reliability.

3.3. Building Information Modeling (BIM)

BIM is a digital representation of a building that includes information about its geometry, materials, and systems. BIM can be used to facilitate the design, construction, and operation of ductwork systems. By integrating ductwork design with the overall building model, BIM can help to identify potential conflicts between ductwork and other building systems (e.g., electrical, plumbing, structural). BIM can also be used to generate accurate quantity takeoffs and cost estimates for ductwork systems. Using BIM throughout the building lifecycle allows for better coordination and clash detection, minimizing errors during construction and operation.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

4. Ductwork Performance and Efficiency

The performance and efficiency of ductwork systems are critical factors in determining the overall energy consumption and indoor air quality of buildings. Ductwork leakage, thermal losses, and improper sizing can significantly reduce the efficiency of HVAC systems, leading to increased energy costs and reduced comfort levels.

4.1. Air Leakage

Air leakage is a major problem in ductwork systems, accounting for a significant portion of energy losses in buildings. Leaks can occur at joints, seams, and penetrations in the ductwork. The amount of air leakage depends on factors such as the quality of the ductwork materials, the installation techniques, and the age of the system. Air leakage can also introduce contaminants into the air stream, degrading indoor air quality. Pressure testing is essential to identify and quantify air leakage in ductwork systems. Various sealing methods, such as duct mastic, foil tape, and aerosol sealants, can be used to reduce air leakage.

4.2. Thermal Losses

Thermal losses from ductwork can occur due to conduction, convection, and radiation. The amount of thermal loss depends on factors such as the thermal conductivity of the ductwork materials, the insulation thickness, and the temperature difference between the ductwork and the surrounding environment. Insulating ductwork can significantly reduce thermal losses and improve the energy efficiency of the HVAC system. The insulation material should have a low thermal conductivity and be properly installed to minimize gaps and voids. Climate zones dictate the appropriate insulation levels needed to comply with energy codes.

4.3. Ductwork Sizing

Proper ductwork sizing is essential to ensure adequate airflow and minimize pressure drops. Undersized ductwork can result in reduced airflow, increased fan energy consumption, and uneven temperature distribution. Oversized ductwork can increase material costs and require more space for installation. Ductwork sizing should be based on accurate calculations of airflow rates and pressure drops, taking into account the specific requirements of the building and the HVAC system. An improperly sized duct system can lead to significant performance issues and energy waste.

4.4. Impact on HVAC System Performance

Ductwork performance directly impacts the overall efficiency and performance of the entire HVAC system. Air leakage and thermal losses can reduce the heating and cooling capacity of the system, requiring the HVAC equipment to work harder and consume more energy. Improper ductwork sizing can lead to reduced airflow, uneven temperature distribution, and increased noise levels. Regular maintenance and inspection of ductwork systems are essential to ensure optimal performance and energy efficiency. Duct cleaning should be performed periodically to remove dust and debris that can accumulate in the ductwork and reduce airflow.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

5. Ductwork Sealing and Insulation Techniques

Effective sealing and insulation techniques are crucial for minimizing air leakage and thermal losses in ductwork systems. This section provides an overview of commonly used sealing and insulation materials and methods.

5.1. Duct Mastic

Duct mastic is a water-based sealant that is applied to joints, seams, and penetrations in ductwork to prevent air leakage. It is typically applied with a brush or trowel and forms a flexible, airtight seal. Duct mastic is relatively inexpensive and easy to apply, making it a popular choice for sealing ductwork systems. However, it is important to ensure that the duct surfaces are clean and dry before applying the mastic to ensure proper adhesion. Choosing a high-quality duct mastic that meets industry standards is essential for long-lasting performance.

5.2. Foil Tape

Foil tape is a pressure-sensitive tape with a foil backing that is used to seal joints and seams in ductwork. It is available in various widths and thicknesses and can be easily applied to duct surfaces. Foil tape provides an airtight seal and is resistant to moisture and temperature changes. However, it is important to use high-quality foil tape that is specifically designed for ductwork applications. Poor-quality foil tape may lose its adhesion over time and fail to provide an effective seal. Overlapping the tape edges is recommended for a better seal.

5.3. Aerosol Sealants

Aerosol sealants are injected into ductwork systems to seal leaks from the inside. The sealant particles are carried by the airflow and deposit at leak locations, forming an airtight seal. Aerosol sealants are particularly effective for sealing leaks in hard-to-reach areas. However, they can be relatively expensive and require specialized equipment for application. Aerosol sealing can be a very effective method for sealing existing ductwork systems, especially in situations where access is limited.

5.4. Insulation Materials

Various insulation materials can be used to reduce thermal losses from ductwork, including fiberglass, mineral wool, foam, and cellulose. The choice of insulation material depends on factors such as thermal conductivity, cost, and ease of installation. The insulation material should be properly installed to minimize gaps and voids. The thickness of the insulation should be selected based on the climate zone and the desired level of thermal performance. Regularly check for damaged or degraded insulation and replace as needed.

5.5. Insulation Methods

Ductwork can be insulated using various methods, including wrapping, spray-on, and pre-insulated ductwork. Wrapping involves wrapping the ductwork with insulation material and securing it with tape or wire. Spray-on insulation is applied directly to the ductwork surface using a sprayer. Pre-insulated ductwork is manufactured with insulation already applied to the duct section. The choice of insulation method depends on factors such as the size and shape of the ductwork, the available space, and the desired level of thermal performance. Properly sealing joints and seams in the insulation is essential to prevent air leakage and maintain thermal performance.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

6. Cost-Benefit Analysis of Ductwork Repairs and Replacement

Decisions regarding ductwork repairs or replacement require a thorough cost-benefit analysis to determine the most economically viable option. This analysis should consider factors such as the cost of repairs, the cost of replacement, the energy savings resulting from improved ductwork performance, and the potential impact on indoor air quality.

6.1. Cost of Repairs

The cost of ductwork repairs can vary depending on the type and extent of the damage. Minor repairs, such as sealing small leaks, can be relatively inexpensive. Major repairs, such as replacing damaged duct sections, can be more costly. The cost of labor should also be considered. Obtaining multiple quotes from qualified HVAC contractors is recommended to ensure a fair price. Regular maintenance can prevent minor issues from escalating into costly repairs.

6.2. Cost of Replacement

The cost of ductwork replacement depends on the size and complexity of the ductwork system, the materials used, and the labor costs. Replacement is typically more expensive than repairs, but it can provide significant benefits in terms of energy savings and improved indoor air quality. The cost of disposing of the old ductwork should also be considered. A comprehensive assessment of the existing ductwork system is necessary to determine the feasibility and cost of replacement.

6.3. Energy Savings

Improved ductwork performance can result in significant energy savings. Reducing air leakage and thermal losses can lower heating and cooling costs and reduce the overall energy consumption of the building. The amount of energy savings depends on factors such as the climate zone, the size of the building, and the efficiency of the HVAC equipment. Energy audits can help to quantify the potential energy savings from ductwork repairs or replacement. Government incentives and rebates may be available to offset the cost of energy-efficient ductwork improvements.

6.4. Indoor Air Quality

Ductwork repairs or replacement can improve indoor air quality by reducing the infiltration of dust, allergens, and other contaminants into the air stream. This can be particularly beneficial for people with allergies or respiratory problems. New ductwork materials may also be less prone to mold growth and other indoor air quality issues. Improving indoor air quality can lead to increased comfort and productivity for building occupants. Regularly cleaning the ductwork system is also important for maintaining good indoor air quality.

6.5. Life-Cycle Cost Analysis

A life-cycle cost analysis (LCCA) should be performed to compare the long-term costs and benefits of ductwork repairs and replacement. The LCCA should consider factors such as the initial cost, the operating costs (energy consumption, maintenance), and the replacement costs. The LCCA should also account for the time value of money (discount rate). The LCCA will provide a comprehensive assessment of the economic viability of different ductwork options. This analysis helps in making informed decisions based on the total cost of ownership.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

7. Latest Technologies in Ductwork Materials and Design

Ongoing research and development efforts are focused on developing new materials and design techniques for ductwork systems. These innovations aim to improve energy efficiency, reduce air leakage, and enhance indoor air quality.

7.1. Smart Ductwork Systems

Smart ductwork systems incorporate sensors and controls to monitor and optimize airflow in real-time. These systems can automatically adjust damper positions to maintain desired temperature and airflow levels in different zones of the building. Smart ductwork systems can also detect and alert users to potential problems, such as air leaks or equipment malfunctions. Integration with building automation systems (BAS) allows for centralized control and monitoring of the ductwork system. Data analytics can be used to identify trends and optimize system performance over time.

7.2. Nanomaterials

Nanomaterials are being explored for use in ductwork insulation and sealing. Nanomaterials can provide enhanced thermal insulation properties and improved air leakage resistance. For example, aerogel insulation materials offer extremely low thermal conductivity. Nanoparticles can also be incorporated into duct sealants to improve their adhesion and durability. However, the cost and potential health and environmental impacts of nanomaterials need to be carefully considered.

7.3. Phase Change Materials (PCMs)

PCMs can be integrated into ductwork systems to store and release thermal energy. PCMs absorb heat during the day and release it at night, helping to stabilize indoor temperatures and reduce peak energy demand. PCMs can be incorporated into ductwork insulation or used as a separate layer within the duct system. Proper integration of PCMs requires careful design and consideration of the specific climate conditions.

7.4. Bio-Based Materials

Bio-based materials, such as cellulose insulation and plant-based sealants, are gaining attention due to their environmental benefits. These materials are made from renewable resources and have a lower carbon footprint compared to traditional materials. However, the performance and durability of bio-based materials need to be carefully evaluated. Certifications, such as those from the Forest Stewardship Council (FSC), can help to ensure the sustainability of bio-based materials.

7.5. 3D Printed Ductwork

3D printing technology is being explored as a potential method for fabricating customized ductwork components with complex geometries. 3D printing allows for the creation of ductwork sections with optimized airflow characteristics and reduced pressure drops. However, the cost and scalability of 3D printing technology need to be further improved. The choice of materials for 3D printing is also a critical consideration.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

8. Conclusion

Ductwork systems are essential components of HVAC systems, playing a critical role in maintaining indoor comfort, energy efficiency, and indoor air quality. This research report has provided a comprehensive review of ductwork systems, covering materials, design methodologies, performance characteristics, and emerging technologies. Key findings from the report include:

- The selection of appropriate ductwork materials is crucial for ensuring performance, durability, and cost-effectiveness.

- Advanced modeling techniques, such as CFD, can be used to optimize ductwork design and predict performance with high accuracy.

- Air leakage and thermal losses are major problems in ductwork systems, significantly reducing energy efficiency and degrading indoor air quality.

- Effective sealing and insulation techniques are essential for minimizing air leakage and thermal losses.

- A thorough cost-benefit analysis should be performed to guide decisions regarding ductwork repairs and replacement.

- Ongoing research and development efforts are focused on developing new materials and design techniques for ductwork systems, including smart ductwork systems, nanomaterials, PCMs, bio-based materials, and 3D printed ductwork.

Future research should focus on developing more accurate models for predicting ductwork performance, evaluating the long-term performance of emerging ductwork materials, and developing cost-effective solutions for improving ductwork energy efficiency and indoor air quality. Collaboration between researchers, HVAC professionals, and policymakers is essential to accelerate the adoption of innovative ductwork technologies and promote sustainable building practices.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

References

- ASHRAE Handbook – HVAC Systems and Equipment. American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- SMACNA HVAC Duct Construction Standards – Metal and Flexible. Sheet Metal and Air Conditioning Contractors’ National Association.

- DOE Building Technologies Office. U.S. Department of Energy.

- ANSI/ASHRAE Standard 152-2021, Method of Test for Air Leakage of Air-Distribution Systems.

- EPA Indoor Air Quality (IAQ). U.S. Environmental Protection Agency.

- https://www.energy.gov/

- https://www.ashrae.org/

- https://www.smacna.org/

- Miller, R. T., & Kramer, D. E. (2012). Duct design: The definitive guide to HVAC duct system optimization. McGraw-Hill Education.

- Eastop, T. D., & McConkey, A. (1993). Applied thermodynamics for engineering technologists. Longman Scientific & Technical.

The discussion on ductwork sealing and the use of aerosol sealants is particularly interesting. Has anyone explored the long-term effectiveness of aerosol sealants in different environmental conditions, especially concerning varying temperature and humidity levels?

That’s a great point! The long-term performance of aerosol sealants is definitely key. We’ve seen promising results in controlled settings, but real-world variations in temperature and humidity are critical to consider. Further research is needed to fully understand the longevity and reliability in diverse climates. I wonder if accelerated aging tests could provide insights? #HVAC #ductwork

Editor: FocusNews.Uk

Thank you to our Sponsor Focus 360 Energy

The discussion on bio-based materials in ductwork is noteworthy. How do these materials compare in terms of fire resistance and mold growth potential relative to traditional options like fiberglass or galvanized steel?

That’s an important consideration! The fire resistance and mold growth of bio-based materials are key factors. While some show promise with fire-retardant additives, and natural antimicrobial properties, comprehensive testing and certifications are essential before widespread adoption in ductwork. We need more data for comparisons!

Editor: FocusNews.Uk

Thank you to our Sponsor Focus 360 Energy

So, about these smart ductwork systems… if my ducts become self-aware, will they demand better music than elevator jazz, and perhaps negotiate for a vacation home near the air handler? Just curious about the fine print on that technology.

That’s a fun question! The idea of self-aware ductwork does bring up some interesting possibilities. While we haven’t quite reached the point of demanding vacation homes, the sensors and controls in smart systems are getting increasingly sophisticated. Maybe custom playlists are the next logical step? Thanks for the engaging comment!

Editor: FocusNews.Uk

Thank you to our Sponsor Focus 360 Energy

Considering the increasing interest in bio-based materials, what are the practical challenges in scaling up production to meet industry demands for ductwork, and how might these be overcome?