Abstract

The ‘Fabric First Approach’ represents a fundamental paradigm shift in the pursuit of energy-efficient and sustainable architecture. This research report champions its foundational role, advocating for the strategic prioritization of the building’s physical shell performance before the integration of complex mechanical systems. The core premise involves the meticulous optimization of insulation, airtightness, and thermal bridging, alongside astute considerations of building orientation and high-performance glazing. This comprehensive analysis delves into the detailed principles underpinning the fabric first methodology, exploring diverse insulation materials and their thermal properties (R-values), advanced techniques for achieving stringent airtightness, and innovative strategies to mitigate thermal bridging. Furthermore, the report examines the multifaceted economic and environmental benefits derived from this approach, critically evaluates the challenges inherent in its widespread implementation, particularly in the context of retrofitting existing building stock, and offers a future outlook on its evolving significance in achieving global decarbonization targets. While acknowledging contemporary debates, this report posits that a robust fabric remains the indispensable bedrock for genuinely sustainable and resilient built environments.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

1. Introduction

The global imperative to address climate change and mitigate its escalating impacts has profoundly reshaped the discourse within the built environment sector. Buildings are substantial contributors to global energy consumption and carbon emissions, accounting for approximately 28% of total energy-related CO2 emissions in 2020 [12]. In response to this critical challenge, the ‘Fabric First Approach’ has emerged as a seminal philosophy, offering a robust and enduring pathway towards greater energy efficiency and sustainability in construction [2, 8]. This approach fundamentally reorients design and construction priorities, advocating for the maximization of the inherent performance of the building’s physical structure – its ‘fabric’ – as the primary means of reducing energy demand [2, 3, 4, 8, 11, 14].

Unlike traditional methodologies that might disproportionately rely on active mechanical and electrical systems to offset poor thermal performance, the fabric first principle asserts that a well-designed and constructed building envelope should inherently minimize energy requirements for heating and cooling [2, 3, 4, 11]. This foundational strategy involves a meticulous focus on elements such as walls, roofs, floors, windows, and doors, ensuring they provide a superior thermal barrier against external conditions [3, 4, 11, 14]. The subsequent sections of this report will systematically unpack the core principles, advanced techniques, tangible benefits, and pertinent challenges associated with the fabric first approach, ultimately offering a comprehensive perspective on its pivotal role in shaping a more sustainable and resilient future for the built environment.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

2. Core Principles of the Fabric First Approach

The efficacy of the fabric first approach hinges upon the rigorous application of several interconnected design and construction principles. These principles collectively aim to create a highly efficient building envelope, reducing energy demand passively before active systems are considered. The core elements include maximizing thermal performance through insulation, achieving robust airtightness, minimizing thermal bridging, and optimizing building orientation and glazing.

2.1 Maximizing Thermal Performance: Super-Insulation

At the heart of the fabric first approach lies the principle of super-insulation, which involves significantly increasing the thermal resistance of a building’s external elements: walls, roofs, and floors [2, 4, 6]. Thermal performance is quantified by U-values and R-values. The U-value (thermal transmittance) measures the rate of heat transfer through a building element, with lower U-values indicating better insulation properties [11, 24, 29, 30]. Conversely, the R-value (thermal resistance) measures an insulation material’s ability to resist heat flow, with higher R-values indicating greater insulating power. The inverse relationship between U-value and R-value means that increasing insulation thickness or using materials with higher inherent R-values directly leads to lower U-values for the building envelope [11, 24, 29].

Various insulation materials are employed, each with distinct properties. Mineral wool (including glass wool and rock wool) is widely used for its excellent thermal and acoustic performance, as well as its non-combustibility. Polyisocyanurate (PIR) and extruded polystyrene (XPS) boards offer high R-values for thinner applications, making them suitable where space is constrained. Expanded polystyrene (EPS) is a cost-effective option, often used in cavity walls and as external wall insulation. Increasingly, natural and bio-based insulation materials are gaining traction due to their lower embodied carbon and potential for improved indoor air quality [5]. Examples include sheep’s wool, cellulose (recycled paper), and wood fibre, which not only provide excellent thermal performance but also contribute to a more stable indoor climate by managing moisture and preventing heat loss in winter and heat gain in summer [5]. The strategic placement of continuous insulation layers is crucial to avoid thermal bypass and ensure uniform thermal resistance across the entire building fabric [6].

2.2 Achieving Airtightness

Airtightness, or the prevention of uncontrolled air leakage through the building envelope, is a critical component of the fabric first approach [2, 4, 6, 8, 11, 13]. Uncontrolled air movement, known as infiltration or exfiltration, can lead to significant heat loss or gain, compromising the effectiveness of insulation and contributing to higher energy consumption [4, 8]. Beyond energy efficiency, robust airtightness is vital for maintaining consistent indoor temperatures, reducing drafts, preventing condensation within the building fabric, and improving indoor air quality by limiting the ingress of outdoor pollutants and allergens [3, 4, 13].

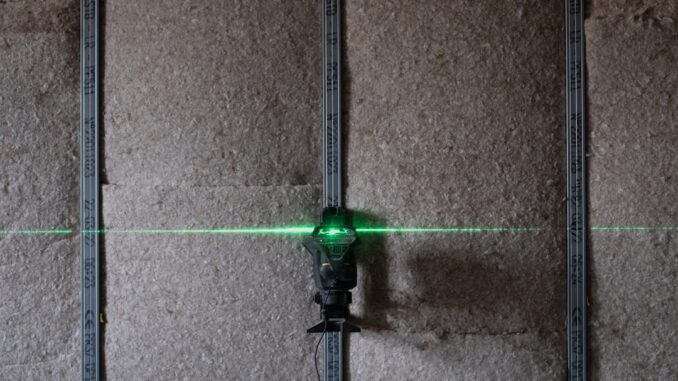

Achieving high levels of airtightness requires meticulous attention to detail during design and construction. Techniques include the careful application of air barrier membranes, specialized tapes, and sealants at all junctions, penetrations (e.g., around windows, doors, pipes, and electrical outlets), and material transitions [7, 10, 13]. Best practices emphasize the creation of a continuous airtight layer around the entire conditioned space. Diagnostic tools such as blower door testing are commonly used to measure the building’s airtightness (expressed in air changes per hour at a given pressure difference, e.g., 50 Pascals) and identify specific leakage points for remediation [10]. Achieving stringent standards, such as those required for Passivhaus certification (0.6 air changes per hour at 50 Pascals), demonstrates the feasibility of extremely high levels of airtightness through diligent application of fabric first principles [10].

2.3 Minimizing Thermal Bridging

Thermal bridging refers to localized areas within the building envelope where heat transfer is significantly greater than in adjacent, well-insulated sections [4, 7, 11, 13]. These ‘bridges’ occur wherever there is a break in the continuous insulation layer, commonly at junctions between different building elements (e.g., wall-floor, wall-roof, wall-window), around structural elements, and at points where services penetrate the envelope [7, 8, 13]. Thermal bridges can lead to disproportionate heat loss, cold spots, surface condensation, and even mould growth, undermining the overall thermal performance and occupant comfort [3, 10, 18].

Minimizing thermal bridging is an integral part of the fabric first strategy, requiring a holistic design approach [12]. Mitigation strategies include: employing continuous insulation layers that wrap around the structural frame; incorporating thermal breaks (materials with low thermal conductivity) within structural connections; designing junctions to avoid direct paths for heat flow; and careful detailing around openings and penetrations [4, 7, 8, 13]. For instance, insulated window frames and recessed window installations can reduce heat loss at these vulnerable points. Advanced simulation software can precisely identify and quantify the impact of potential thermal bridges during the design phase, allowing for proactive design solutions [6]. The goal is to ensure a consistent and effective thermal barrier across the entire building fabric [4, 7].

2.4 Optimized Building Orientation and Glazing

The strategic orientation of a building and the careful selection of its glazing play a crucial role in harnessing natural energy flows and mitigating unwanted solar gain or heat loss, thereby minimizing reliance on mechanical heating and cooling systems [2, 4, 6]. This passive design strategy involves positioning the building on its site to maximize beneficial solar exposure in colder climates (e.g., large south-facing windows for passive solar gain in the Northern Hemisphere) and to minimize undesirable solar heat gain in warmer climates (e.g., limiting west-facing glazing) [4, 6, 10]. Shading devices, such as overhangs, fins, and brise soleil, are integrated to control solar penetration throughout the year, allowing winter sun in while blocking harsh summer sun [2, 4, 6].

High-performance glazing is a critical component of this principle. The performance of windows is primarily characterized by two key metrics: the U-value and the G-value (or Solar Heat Gain Coefficient, SHGC) [15, 24, 29, 30]. The U-value for windows (Uw) indicates heat loss, with lower values signifying better insulation [15, 29]. High-performance glazing typically includes multiple panes (double or triple glazing), inert gas fills (argon or krypton) between panes, and low-emissivity (low-e) coatings. Low-e coatings are microscopic metal layers that reflect infrared radiation, keeping heat inside in winter and outside in summer [15, 30]. The G-value represents the fraction of solar radiation transmitted through the glass, where a higher G-value indicates greater solar heat gain [15, 24, 29, 30, 31]. In cold climates, a higher G-value can be beneficial for passive solar heating, while in warm climates, a lower G-value is preferred to reduce overheating [15, 24]. Balancing daylighting requirements with solar control is paramount to optimize occupant comfort and reduce the need for artificial lighting and air conditioning [30]. The window-to-wall ratio is also a critical design consideration, as large expanses of glass, even high-performance ones, can still be a weaker point in the thermal envelope compared to an insulated wall [6].

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

3. Advanced Techniques and Materials in Fabric First Design

The evolution of the fabric first approach is continually driven by advancements in material science, construction methodologies, and digital technologies. These innovations enable designers and builders to achieve unprecedented levels of building performance and sustainability.

3.1 Innovative Insulation Materials

Beyond conventional insulation, cutting-edge materials offer enhanced thermal performance and unique properties. Vacuum Insulated Panels (VIPs) consist of a rigid, evacuated core sealed within an impermeable envelope. They offer exceptionally low U-values for minimal thickness, making them ideal for space-constrained applications or for mitigating stubborn thermal bridges [11]. Aerogels are highly porous, low-density solids derived from a gel, offering extremely low thermal conductivity and good light transmission, suitable for translucent insulation applications. Phase Change Materials (PCMs) can be integrated into building fabric elements to absorb, store, and release latent heat as they change phase (e.g., from solid to liquid), helping to regulate internal temperatures and reduce peak heating/cooling loads. Furthermore, the focus on sustainability has spurred the development and adoption of bio-based and recycled insulation materials, such as hempcrete, wood fiber, and recycled denim, which offer competitive thermal performance alongside reduced embodied carbon footprints and often superior breathability [5, 12].

3.2 Smart Building Envelopes

The concept of a ‘smart’ building envelope moves beyond static performance to dynamic responsiveness. Dynamic facades, for instance, can adapt to changing external conditions by adjusting shading, ventilation, and even transparency, optimizing daylighting, solar gain, and thermal comfort throughout the day and year. Building Integrated Photovoltaics (BIPV) represent another significant advancement, where solar photovoltaic cells are seamlessly integrated into the building fabric (e.g., roof tiles, facade panels, or even glazing), generating electricity while simultaneously providing weather protection and aesthetic appeal. Green roofs and living walls, while not strictly insulation in the traditional sense, contribute to thermal mass, reduce urban heat island effects, manage stormwater, and provide additional insulation, particularly against solar gain in summer.

3.3 Prefabrication and Off-site Construction

Prefabrication and off-site construction methods are increasingly recognized for their ability to enhance the precision and quality required for high-performance building envelopes [2]. By manufacturing building components, such as insulated wall panels or roof cassettes, in a controlled factory environment, it is possible to achieve far greater accuracy in terms of insulation continuity and airtightness detailing than typically achievable on-site [2]. This controlled environment minimizes errors, reduces waste, and allows for stringent quality control measures, directly translating into superior fabric performance upon assembly. The increased speed of build and reduced on-site labor costs are additional benefits, making high-performance construction more efficient and predictable [2].

3.4 Digital Tools and Simulation

The complexity of optimizing building fabric performance necessitates sophisticated digital tools. Building Information Modeling (BIM) platforms allow for integrated design, visualization, and analysis, enabling design teams to model the building envelope in detail, detect potential thermal bridges, and ensure coordination between different building systems. Thermal modeling and energy simulation software, such as PHPP (Passive House Planning Package) and EnergyPlus, are indispensable for predicting a building’s energy performance based on its fabric characteristics, climate data, and occupant behavior [6, 10]. These tools enable designers to test various scenarios, optimize insulation levels, window specifications, and shading strategies, and accurately predict energy demand, thereby de-risking the fabric first design process and ensuring that theoretical performance translates into real-world efficiency [6].

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

4. Economic and Environmental Benefits

The widespread adoption of the fabric first approach yields a multitude of significant benefits, extending far beyond immediate energy savings to encompass long-term economic advantages, enhanced occupant well-being, and substantial environmental contributions.

4.1 Long-term Operational Savings

The most direct and tangible economic benefit of a fabric first approach is the substantial reduction in operational energy consumption over the building’s lifespan [2, 3, 4, 5, 7, 11]. By significantly improving insulation, minimizing air leakage, and optimizing passive solar gains, the demand for active heating, cooling, and often artificial lighting is drastically reduced [4, 7, 8, 11]. This translates directly into lower energy bills for occupants or building owners, providing significant cost savings over decades [3, 4, 5, 7, 11]. Unlike mechanical systems that require regular servicing and have limited lifespans, properly installed building fabric components, such as insulation and airtightness layers, are durable and require minimal maintenance, ensuring continuous energy savings without ongoing intervention [2, 5, 11]. This long-term financial prudence makes the initial investment a highly effective capital expenditure [4, 5].

4.2 Enhanced Occupant Comfort and Health

A building designed with a fabric first methodology inherently offers a superior indoor environment. The stability of internal temperatures, achieved through high levels of insulation and airtightness, minimizes uncomfortable fluctuations and eliminates cold spots and drafts [3, 4, 7, 11]. This consistent thermal comfort creates a healthier and more pleasant living or working space for occupants [3, 4, 7]. Furthermore, when coupled with controlled mechanical ventilation systems (e.g., Mechanical Ventilation with Heat Recovery – MVHR), improved airtightness can lead to better indoor air quality by preventing uncontrolled infiltration of pollutants, allergens, and moisture, while ensuring a steady supply of fresh, filtered air [3, 6, 10, 13]. Reduced drafts and improved envelope performance also contribute to enhanced acoustic comfort by dampening external noise [3].

4.3 Environmental Impact Reduction

The fabric first approach plays a crucial role in reducing the environmental footprint of the built environment. Primarily, the significant reduction in heating and cooling demand directly leads to lower operational carbon emissions, which are the greenhouse gas emissions associated with the energy used to run a building [2, 3, 4, 7, 11]. This directly contributes to national and international decarbonization targets and efforts to mitigate climate change [2, 4, 7, 12].

However, it is vital to consider embodied carbon – the emissions generated throughout the entire lifecycle of building materials, from extraction and manufacturing to transportation, construction, and eventual demolition or disposal [9, 12, 23]. While fabric first prioritizes durable materials, the choice of these materials significantly impacts embodied carbon. Using sustainable, natural, or recycled materials (e.g., timber, cellulose, hemp) can substantially lower the embodied carbon footprint [5, 12, 23]. There is an ongoing debate, particularly in retrofitting existing buildings, regarding the balance between the embodied carbon incurred by extensive fabric upgrades versus the operational carbon savings. Some argue that in the face of rapid grid decarbonization and the urgent need to deploy low-carbon heating technologies like heat pumps, a ‘fabric first, but not fabric only’ or even ‘fabric sometimes’ approach might be more pragmatic for existing stock, as the embodied carbon investment of deep retrofits can be significant in the short-to-medium term [1, 9, 32]. Nevertheless, for new builds and well-planned retrofits, the long-term benefits of reduced operational energy, combined with careful material selection, ensure that the fabric first approach remains a net positive for environmental impact reduction [12, 28].

4.4 Increased Building Resilience and Value

Buildings constructed with a fabric first ethos are inherently more resilient and durable. The emphasis on high-quality materials and meticulous construction detailing results in a more robust and longer-lasting building envelope [3, 5]. This improved durability offers enhanced protection against extreme weather events, which are becoming more frequent due to climate change. Moreover, such buildings are less susceptible to issues like condensation, moisture ingress, and degradation, contributing to a lower maintenance burden and extending the building’s lifespan [2, 3, 5]. In a market increasingly prioritizing sustainability and energy efficiency, fabric first buildings often command higher asset values and attract environmentally conscious occupants, leading to increased marketability and rental returns [28]. This enhances the overall financial viability and future-proofing of the investment.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

5. Challenges and Barriers to Implementation

Despite the undeniable advantages of the fabric first approach, its widespread adoption faces several challenges and barriers. These often stem from a combination of economic, technical, and systemic issues that require concerted effort to overcome.

5.1 Initial Capital Cost

One of the most frequently cited barriers to implementing a fabric first approach is the perception of higher upfront capital costs compared to conventional construction [4, 7]. While superior insulation, high-performance glazing, and meticulous airtightness detailing often require a greater initial investment in materials and labor, this perspective often overlooks the long-term financial benefits [4, 7]. A comprehensive cost-benefit analysis, considering the entire lifecycle of the building, invariably demonstrates that the operational savings in energy bills and reduced maintenance costs typically outweigh the initial premium [4, 5, 7]. However, traditional financing models and developer mindsets often prioritize upfront expenditure, making it challenging to justify higher initial costs without clear, immediate returns. Education on lifecycle costing and the integration of long-term value into financial models are crucial to addressing this barrier.

5.2 Knowledge and Skill Gaps

The successful execution of a fabric first approach demands a higher level of technical knowledge, precision, and skill from all stakeholders involved in the design and construction process [4, 7, 19, 26]. Architects and designers require expertise in passive design principles, advanced material selection, and sophisticated thermal modeling. Contractors and tradespeople need specialized training in installing continuous insulation layers, achieving rigorous airtightness, and eliminating thermal bridges [4, 7]. Current training curricula and industry practices in many regions have not yet fully adapted to these demands, leading to a significant knowledge and skill gap [4, 7, 12, 26]. This deficit can result in a ‘performance gap,’ where the actual energy performance of a building falls short of its designed potential due to poor execution on site [5.4 below]. Addressing this requires substantial investment in education, professional development, and collaborative training initiatives across the construction supply chain [12, 27].

5.3 Regulatory and Policy Frameworks

While many building codes are evolving to encourage greater energy efficiency, the stringency and enforcement of these regulations vary significantly across different jurisdictions [16, 20, 21]. In some regions, minimum building codes may not be ambitious enough to truly drive fabric first principles, allowing for less efficient construction that relies on mechanical systems to meet basic performance requirements [1, 16, 20]. Model energy codes, such as the International Energy Conservation Code (IECC) for residential buildings and ASHRAE Standard 90.1 for commercial buildings, are updated on a three-year cycle, continually pushing for higher performance [16, 20, 21]. However, their adoption by state and local authorities is often delayed or includes modifications, creating inconsistencies [21, 27]. A lack of strong policy signals, financial incentives (e.g., grants, tax breaks for high-performance buildings), or clear enforcement mechanisms can hinder widespread adoption of fabric first principles, especially when market forces alone are insufficient to overcome the perceived initial cost barrier [4]. The move towards Building Performance Standards (BPS), which set targets for energy use or emissions in existing buildings, represents a positive policy shift [22].

5.4 Performance Gap

Even with well-intentioned designs, a notable ‘performance gap’ can emerge, where the actual operational energy consumption of a building significantly exceeds its predicted performance [9]. This discrepancy is often attributed to shortcomings in the construction process, such as poor quality control, inadequate commissioning of building systems, or issues with occupant behavior [9]. Factors like unforeseen thermal bridges, breaches in the airtightness layer during installation, or incorrect specification of materials can all contribute to this gap. Mitigating the performance gap requires rigorous quality assurance throughout the construction phase, detailed commissioning processes to ensure all systems perform as designed, and comprehensive post-occupancy evaluation to monitor actual energy use and gather feedback for future improvements. Digital tools like BIM and energy simulation can help predict performance, but their effectiveness depends on accurate input data and precise execution on site [6, 10].

5.5 Retrofitting Existing Buildings: A Complex Debate

The application of the fabric first approach to retrofitting existing buildings presents distinct challenges and is the subject of considerable debate [1, 9, 17, 32]. While the core principle of reducing demand through fabric improvements remains sound, the practicalities and cost-effectiveness can be more complex than for new builds. Older buildings often have unique construction methods, heritage considerations, and structural limitations that make deep fabric retrofits technically challenging and expensive [1, 17, 28]. For example, insulating solid walls is more disruptive and costly than cavity wall insulation [17].

Furthermore, a significant point of contention revolves around the sequence of decarbonization measures, especially in the context of electrifying heating through technologies like heat pumps. Some argue that a strict ‘fabric first’ sequence – where extensive fabric upgrades must precede the installation of low-carbon heating systems – can delay overall decarbonization efforts, particularly for the vast existing building stock [1, 9, 32, 33]. The argument is that while heat pumps perform best in well-insulated homes, their efficiency has improved, and the carbon intensity of electricity grids is rapidly declining [33]. Therefore, prioritizing the rapid deployment of heat pumps, even in homes with moderate fabric improvements, might yield quicker and more significant carbon emission reductions, especially considering the high embodied carbon associated with deep fabric interventions in existing buildings [9, 32, 33]. The low uptake rate of deep retrofits in the EU (around 0.2%) suggests that an ‘all-or-nothing’ fabric first approach for existing homes might be too slow for urgent climate targets [1].

In my opinion, while the ‘fabric first’ mantra remains the ‘golden rule’ for new construction due to its inherent long-term benefits and ease of integration from conception, a more nuanced and flexible approach is warranted for existing buildings. This does not diminish the importance of fabric improvements but rather suggests that the optimal strategy for retrofit should consider a ‘whole-house’ approach that balances fabric enhancements with the immediate deployment of low-carbon heating, prioritizing measures based on cost-effectiveness, feasibility, and overall whole-life carbon impact [9, 17, 18, 32]. Crucially, even when heat pumps are installed, a degree of fabric improvement (such as draught-proofing and loft insulation, which offer high returns) is almost always beneficial to ensure optimal system performance and occupant comfort [17, 18, 33]. The goal should be to reduce demand as much as practically and economically viable, without allowing extensive fabric work to become a bottleneck for rapid heat decarbonization.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

6. Case Studies and Best Practices

The principles of the fabric first approach are best exemplified by projects that successfully integrate high-performance building envelopes with holistic design strategies. While specific named projects are outside the scope of detailed individual analysis here, the global proliferation of buildings adhering to standards such as Passivhaus offers compelling evidence of fabric first’s efficacy. The Passivhaus standard, renowned for its extremely low energy consumption, fundamentally relies on rigorous fabric performance, including ultra-high levels of insulation, exceptional airtightness, thermal bridge-free design, and optimized passive solar gain [6, 10]. Commercial buildings and public structures are increasingly adopting similar principles, recognizing that the long-term operational savings and improved indoor environments justify the initial investment.

Best practices in fabric first implementation consistently highlight the importance of an integrated design team. This involves close collaboration among architects, structural engineers, mechanical engineers, and energy consultants from the earliest stages of a project [12]. Such collaboration ensures that passive design strategies are prioritized, potential thermal bridges are identified and mitigated early, and the building services are appropriately sized to meet the reduced energy demand [9, 12]. Quality assurance during construction, including detailed site inspections and testing (e.g., blower door tests), is also paramount to ensure that the designed performance is achieved in reality and to minimize the performance gap. Lessons learned from successful projects underscore that attention to detail, skilled craftsmanship, and a commitment to rigorous performance standards are as important as the choice of materials themselves.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

7. Future Outlook and Recommendations

The fabric first approach is not a static concept but an evolving cornerstone of sustainable construction, continuously adapting to new technologies, environmental imperatives, and policy shifts. Its future significance is inextricably linked to the global trajectory towards net-zero carbon emissions in the built environment.

7.1 Policy and Regulatory Evolution

The trajectory of building regulations is increasingly aligning with fabric first principles, with many jurisdictions moving towards more stringent energy efficiency standards [16, 20, 21, 27]. Future policies are likely to push further, with net-zero operational carbon becoming a mainstream requirement, necessitating robust building envelopes as a prerequisite [4, 6]. Carbon pricing mechanisms, stricter emission targets, and mandatory Building Performance Standards (BPS) for existing buildings will further incentivize fabric improvements [22]. Governments must continue to strengthen building codes, provide clear guidance, and offer financial incentives (e.g., grants, low-interest loans, tax credits) to stimulate investment in high-performance building fabric for both new construction and retrofits [27].

7.2 Technological Advancements

Continued innovation in materials and construction techniques will further enhance the fabric first approach. Research into advanced insulation materials, such as next-generation aerogels, self-healing envelopes, and dynamic smart materials that can respond to environmental changes, will push performance boundaries [9]. The integration of artificial intelligence and machine learning with BIM and building performance simulation tools will enable even more sophisticated design optimization, predicting performance with greater accuracy and identifying optimal material combinations and construction methods. The growth of off-site manufacturing and modular construction will also facilitate higher quality control and faster, more precise assembly of high-performance building components [2].

7.3 Integration with Renewable Energy Systems

While fabric first prioritizes demand reduction, it is not an isolated strategy; it serves as the essential foundation for optimizing the effectiveness of on-site renewable energy generation [11]. A building with minimal energy demand can meet a significantly larger proportion of its needs from relatively smaller and more cost-effective renewable energy systems, such as rooftop solar photovoltaics (PV) or small-scale wind turbines [11]. This synergistic relationship ensures that investment in renewables yields maximum impact, pushing buildings towards genuine net-zero or even energy-plus status. The future will see even more seamless integration of BIPV and other renewable technologies directly into the building envelope.

7.4 Lifecycle Thinking: Beyond Operational Carbon

Increasing emphasis will be placed on whole-life carbon assessment, encompassing both operational and embodied carbon [9, 12, 23]. This holistic view will drive greater consideration of material selection, favoring those with lower embodied carbon footprints, such as sustainably sourced timber, recycled content, and locally produced bio-based materials [5, 12, 23]. Circular economy principles, focusing on designing for disassembly, reuse, and recycling of building materials, will become integral to fabric first design, minimizing waste and maximizing resource efficiency throughout the building’s entire lifecycle.

7.5 Recommendations

Based on the analysis, the following recommendations are put forth:

- For Policymakers: Implement and enforce more ambitious, outcome-based building energy codes; develop consistent Building Performance Standards (BPS) for existing stock; establish robust financial incentives for fabric improvements; and invest in large-scale training and accreditation programs for construction professionals [4, 7, 16, 27].

- For Industry Stakeholders (Designers, Contractors, Developers): Embrace integrated design processes from project inception; invest in continuous professional development for staff on fabric first principles and advanced construction techniques; adopt digital tools like BIM for performance modeling and quality control; and prioritize transparent reporting of both operational and embodied carbon metrics [6, 9, 12, 23].

- For Researchers: Continue to innovate in materials science for enhanced thermal performance and lower embodied carbon; conduct more real-world post-occupancy performance monitoring to close the performance gap; and develop comprehensive methodologies for whole-life carbon assessment that are easily accessible and scalable.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

8. Conclusion

The ‘Fabric First Approach’ stands as an indispensable and evolving strategy for navigating the complexities of sustainable development within the built environment. By strategically prioritizing the maximization of the building’s inherent shell performance—through super-insulation, meticulous airtightness, thermal bridge mitigation, and optimized passive design—it establishes a robust and durable foundation for energy efficiency [2, 3, 4, 11]. The profound economic benefits, including significant long-term operational savings and increased asset value, are complemented by enhanced occupant comfort, improved indoor air quality, and substantial reductions in operational carbon emissions [3, 4, 5, 7, 11].

While challenges persist, particularly concerning initial capital outlay, the imperative for specialized skills, and the nuanced application to retrofitting existing building stock, the strategic importance of a high-performing fabric remains undeniable [4, 9, 32]. The debate around ‘fabric first’ in retrofit emphasizes the need for a holistic, ‘whole-house’ perspective that balances fabric improvements with the timely deployment of low-carbon heating technologies, ensuring that practicality and overall decarbonization targets are met [9, 17, 33].

As regulatory frameworks become more stringent and technological advancements continue to emerge, the fabric first approach will only grow in its critical importance. It is a philosophy that minimizes reliance on active mechanical systems, reduces vulnerability to energy price fluctuations, and fosters resilient, comfortable, and environmentally responsible buildings for future generations. Embracing and refining this approach is not merely an option but a strategic imperative for a truly sustainable built environment.

Many thanks to our sponsor Focus 360 Energy who helped us prepare this research report.

References

[1] Eight Versa. (2024, January 25). Fabric First is Dead. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQEo-tSmjLSNIbzAgcR6aGEwyuJf_0G9-2JvqslpAlS2HxObrb2zYx84Ltht4LCsg_aLe7RafT-LoLLMhWHYFykBCcAmWhq93Y2WhLE-u3ykAQoRRavFzyeLz3LT8UqdCqKBFjjtWFFe3E-KMbFNcqYuK_ZrUefeXr00hJc0pc=

[2] Designing Buildings Wiki. (2021, November 22). Fabric first. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQHm-mjC7sMQJA-d1erazsGxRO2G70_3UpAvwofuroeIdcVlgdKuRyTaXKsrT-J8BKrwrfpd4-LSLQ-f_kf-Ln-IZLx7swKPAj_zczUtVJb-sR_HsSc4MHDWVikdoufeKqiGFpG-fNxSsgTclW6TVBqf=

[3] Kulkarni, G. (2023, March 9). Why a fabric-first approach maximises energy efficiency in sustainable buildings. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQG2_ZcCuvFaUpQ1f7Bycnc8iPGNgibvvbaVVEB8LyeLYojTJnDADu5tDI7SPijDVz62DJJCNOY49A1HuyRKcJCI3dGeK3HjkpOWDKpXFM7OxD2PiJvCRkC0NFLRyuj1QbzJ4cV0z_6koeUHJrjV7v1PShrP9Ag-25R5QbpU5gpKA3RqRx5vjUax_syusHsFZ1j7_lvTBt-uB4msut3yOAF6tAPL0VNjme9P7P6rEb3qqvzOPJZEkrl1xw==

[4] LivGreen. What Is A Fabric First Approach To Decarbonisation?. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQF4XxfEfZjI0Dsg6VHPASb6ph89QiFaY-F5HKGcFzQU8HiYjTJyJ_GoIA0GbL2zZENzJzsVG7jEwLaKmP9TDEeZqfndu4NXQUEjPVhxu2Z-pkswi6p4kl-2YbXfDUK_hfQQJr3MOYk-jqUs=

[5] Ecomerchant. (2025, April 7). Tailoring an Eco-Conscious Living Space: Fabric First Natural Bio-Based Materials Explained. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQEHs1XD_QFaufZLKNtfEez505UgiiIC2RKtjtMDHiALAENqA6nxlD-FB29zHT5dKkoIkYWC5PuoqWuODozmL-TUet9nav4uHcPXpmbPGG7b_pq1p7ngAKgkF7gS09mOZS0CiktUPvjSV-PEwigZs4JfKyGRztjyql2Rcl6Jov0AGDcCWbp9J0IDTumkSEiDXKs=

[6] L+ Architects. (2024, April 26). The Fabric First Approach. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQGoTF6aZLiAR3f_Z6KraNFCC7FPuF5uBQjiShbiiGrDXyqQAwSrXJhgu_tlujzcvxSK0aMGbsBXreMn-IyW5_j-JUQwXaCG1AJJE-htAzrYgrbwtRmM-_L8VhTCIfVClj9yyCGK6JrlK-8WUN8=

[7] RISE – Retrofit. Advice Pack Understanding the fabric first approach. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQGX7c7Hoy_Ias8tcpBBYElTpt5kwBB0Anctm80tVsUXlOecWfSQMaEd97loKkSiIbfW0od7rTQzfuwNeLXjMCgf1s-AsxoCZF2qkiM8b6H_Y84cZzmvr8M7Xpr_Ftw02oWtQ5qwjbtNgiZ3y93m1V848Pc_bHhFBh_bUx434JiBLxxxGbUwBZRdW77ZA7d9BKz9-OU6jlDLUL4_icd8Ij3n=

[8] Roofspace Solutions. What is a Fabric First Approach?. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQGlbbJIWGmW5KwJYYFSDKX_9SQVodcqBRIq0yT6I_k13QHfoAfAMYohmswwbDdZhwxcEUX2lE9rwRUi2w2dLl4ZtYRFCt3dSTESaFhz-xdNFGcqmVvd_u3HMmB5tYCkg6QcmOJMsOT_G_9TswAwIzE1ovhXoIU=

[9] CIBSE Journal. (2023, June 25). Beyond the fabric first approach. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQHkjzTzaHk7BN6zV_kZB5IDi8YMT4kkqDsS6d48c79pyWeHd71QESEtdemTta3R4uhFTSTpXZK-_01q_ZHtVi6hw8AwngMS2LLe0PMu8z1Ay8uIfzm-JvF0B46iH4JpFW0CgGP-59nlDctnsTq8BBy5UFu4h7Hs1JK1Z1Ln8NZ10Q==

[10] Architecta. (2025, February 17). Fabric First Approach. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQGzRQs2FTt0s-F-1TsWYeXDEzWxfZ4ThRIo8IQE7U9qakHvV_kC2m37-dOWfrVpWGsGe2ekqBr5gONXiJyFa2YI5uBxFL4yGoAPTIOct3wDZY-pZ1IMk01BWzhGd1AwLqiEnsVoaDT2t6HJyx6Iw==

[11] Kingspan GB. (2024, August 20). Why fabric first?. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQEuBGaRVeyeZ1clFPkjhIwbonuaMLD9NAbmRD-DymSrq95EZnJKgIVwd3uXw3noFVRpEWEk_2rlrnLGBa3BH7z_HbkBvpxGo6Qvl3kBFEmpqNcq7V9DGW-6arGCxLiDooWE1WR3fHwUT6Ouw2PK7JlE2YYsDPRvY6gmgWEDBg==

[12] BE-ST. (2022, June 1). How to build fabric first. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQGhAEtuWgauoVSeKUXHyBw5mdVjY_MHCX4pfMnzCGOrbECtCproc1k4o4doxRp_uCAa5ZPZQMOlBf4dytgS5cgiyGvCg2DraATK8vQzCvu74z0iDrmB2f9IRFsZWhaoeyAyfEuHTXPsEzuZAq6QX4qqhw==

[13] Nicholson Roof Products. How ROOFBOX Supports the Fabric-First Approach. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQHq0SiYbSvi14QrYDtL3cKCvXkB9OMY0xj10LpIcuPWYsSBzUiM9gds2RKhUEYLs9oDqEIt_aoqKeEhaHRb_O6cezYTlegihUt0z8UIUnyipmg5MpCc1rdFPy4caCTp1BKoSHR8HHuQYV0RfFBXqHvkFHKy7lnIz5_eqWb7j_ZBJYO2iNqsZhi2AK0Gz0pRMw==

[14] Saint-Gobain Self-Build. An easy guide to the fabric first approach. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQF31EKn7l5IM4z76VGXKfbuxfxlHOxREai9ndX4mmPlukRerzfhWGAme0MieqtBxj2Fm14Mv5n1rRNsR-OUBw1UFy6qvq7WrLhq7TVRg1CTQyz-e9o76bvOom-7phYg4z-qZlk_HlqtLI4C-DI87vD-CRL5Xn5nL2W8Z1OGsB3LHZrhpNEKwmPF=

[15] Glass for Europe. (2023, September 21). Choosing ‘High energy performance’ glazing in windows. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQGvnWcIb5MjieQvoV94MLT3BFQOxK0ReR7nlq3S8jdnkvvK1AKLZ4NmOp5GyvXy_bVTolg7XJ84TNZczhOjJ6x-pS-nm9MSmcda6g2a72JLJEehpvKTUKQGKgfsZpkC2E7fpITNK11rNc5JWU9jQsj309LEqgHDlwnw-Wuzpc0jxPbnshGzMQNGWA==

[16] Building Energy Codes Program. Codes 101. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQH79_QROh3snYR-YLiHPcmf-J8BBlP6FVyqhk9Q0BzUZMG_82ro00AaQSDdGqleLu18zto1OkCU7KHKw8RNHCrHx5x_G-gHpSvX4nd_PY3DugnBA5h_HUaQORt2kUYQfQ==

[17] SELCE – South East London Community Energy. What is Retrofit, Where do a Fabric First and Whole House Approach Fit In?. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQFHyb4_bH0SnTqsi0AxH7O_lZpdHbzAVTi8VQ_-KMAVV0JwyLXvm9vAQa11hORLkGs8p97Xj0SVICCDPpRUiQpYCcTq2J1t9nFmrl9FEpBgrQ3Ve5AkNQsg6H-VPUAlBReavE874O6xiGrOroFEu9p1PcUg-4heRAWIvWva69GTenno7-r1qvMJxDjwduXmHL_cB-A==

[18] Solid Wall Insulation Guarantee Agency. Optimised Retrofit Means Fabric First. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQG6cVvb_srUq-uvSYLzVgjPINgWFvmTcf1M_u-ZAubkLZ8gOw99WN6hjm8tYr_M6P9lPVt5YTXvYn699ykWF4vqWcpoN94MYehWX_vNoxosgbbLkljlfGUhZurXzeSPzkbsyanj7oEpXWw0YX3cgjvay-l94sLNNdKFgafrw7DSnlfe=

[19] P3 Adaptive. (2025, May 11). How to Overcome Common Microsoft Fabric Implementation Challenges. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQGzopGwcTr7bN9ZlXpXUZHANV-mUcZMGTFRQFfHy_tHDdWb7gSaE0nVQ904bGpGu2YT5n6eeF-NE-T4-cLPVE6PRV6Q5IVfTLBj5LomsIUkwrF4pdYYGjYUmGxOxZEbI5kkTaZxgcXLVwyzc4Lpf5vWmL9u8oh-7s8lUV13g5aTJeTzyHFWg9dEi0KHz1BFMHmokj9FXDSXvQ==

[20] Whole Building Design Guide. Energy Codes and Standards. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQH_CJYFinkUPsiwbBiXIF16xInaTO8yb3Uz7kFaD3Zj3ja0exwY_AnRdtgxiNHZkjFGiJ27v_OOx9FFT5x-fWmmWm_k_snYwahP2etJIyDcgE5arYvwgWFiaxxtvHVVblDxhs8EUcFqgYDz49kaE1zIG2gs=

[21] NFRC Consumer Guide to Windows. Performance Standards: Building Codes Overview. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQHgMa-aLTw7tUMyanm9ceqegY96RpaU8QxpZuUU3z1X6QzYl1AyP8vIdaQDiHqf6J1_LubgEDIoQJhSKfC1tIYNpYA9xlAXM6s7hA54fuwiYuVBESthgmll_iX4FNCNVnvjhM3Z97JWl4szlYRLQw==

[22] Building Energy Codes Program. Building Performance Standards. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQHJIhxuPzNReByCIy6sfxyX-eiwfe0Fv5JFakdtnbgbAvVZopSEBzIg8g2Zf4iqR551bhEiASCO7LyFrBmjEJYL8dKkwXK9XCzIyRmxve0sinATcfxftizpFg==

[23] Arbor Architects. (2024, June 13). Understanding Embodied Carbon in Architecture – Part 1. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQFX-f0WNBpWuTIe4vCzckWyjg58GLwHALcszUne004mJcmVxAWb3WjaPwSdzrpl5_YLjYry5pIszI-Qx0j2AO7N-b2XiVStAIRSNzYxO_f3KvYhu8jf45emh7W76CH18MOEI565QbA34ksSl7i_ezXaGB3wQQDHw3zZxdnF_tbQ=

[24] Guardian Glass. High-performance glass products. Retrieved from https://vertexaisearch.google.com/grounding_api_redirect/AUZIYQFC43Rn8sXofeWzj3bDIFbBiMKUf3zAZ75DWKuTz2y0rX_0cb6dacw06FbGPI7lTb_SdPpxgeZJe1fsVzi4rhwe3_bb0Z0CXTa35F8grUu0CNyIdGOpH5seP4NDjhOKhiFYoxa25kBsWKfN6FUwqgM3wxiCwxQozAXOmh0qOWcKWCd_LxBRaJT3VsE

[25] P3 Adaptive. (2025, May 11). How to Overcome Common Microsoft Fabric Implementation Challenges. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQGzopGwcTr7bN9ZlXpXUZHANV-mUcZMGTFRQFfHy_tHDdWb7gSaE0nVQ904bGpGu2YT5n6eeF-NE-T4-cLPVE6PRV6Q5IVfTLBj5LomsIUkwrF4pdYYGjYUmGxOxZEbI5kkTaZxgcXLVwyzc4Lpf5vWmL9u8oh-7s8lUV13g5aTJeTzyHFWg9dEi0KHz1BFMHmokj9FXDSXvQ==

[26] HSO. E-book: Why Microsoft Fabric – risks and opportunities. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQFIg_DfcqH6ED75hyM891Kv0e96Q2Uua5_hablUo1WwbvMKVet6_blwLWdWUimd6e3D9nciRuuDv9O7Xbz0xVtPtgmPVAu_hmoC4ITMBomcsNi5mkxnX9OwP_V7NODUdnJ15UNuqpZM-MTG0gO1faRwXCBCFNAb-xOhxYjhshV1tcrXGa3aSDVPKY6qYMbVgEUN6LR8FYtq_SD49SZlN70d0IxBL01BF4rBU4QLeodp7ORS0pZIhEB8

[27] Building Energy Codes Program. Building Energy Codes Program. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQGFO_e96DY72CCrghFjVnHjMmqUasANbBvE4cQb-Gz7Cp5m70x-uksdXBqPiedSRxiYJDCusuu6fjflrK41IDNbb5hCek053Aa0mZ8zdOy-O_3CiusbjgYUu2HI-2u6rbq0KVKZBNEuYL1BLe433fXFl6InXo6BMWAShdKmPQ==

[28] MODUS | RICS. (2023, November 3). What a retrofit-first approach offers the UK. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQHiU7n4zmnbT1FQSKMt-eCqAJ9AmCK4UeqYKfy6l_9Qx9EUQqnEKiVCVKSH6TQtEkLuvnMMn3JnaFL-crDVLiha57zy1Ra-f2G6eLZvrzYayidYPbdjz8G8kDT5Zb0BbdzFsqlHyZXuNKGvL9_FKc2L76jf5pHkrI2ySKl0B2KiwiWGuLwFtSEdNpK9

[29] 21 Degrees. Understanding Windows: U Values, Psi Values & G Values. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQHR2Kq9kJ–RNDY2r543030NTev_YRjuoJRe1ycMpVGKcJ0zQiae50liqmTdrLoPldPs5j-894aEk-r3Eq7w4vhDYLiNdGvgrumgKnVSc83uQxIQp_lwGpvb57QpwB63yeg4_Vtb-kx8_Q_QOVDYZQMvs2HUrag8fYrKll5tcFRRHsi2xlMhzn04MOUK0acOw==

[30] Glazing Vision. (2023, December 19). What you need to know about rooflight U-values. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQFJq-PUfnZ3-DUNIJd7kDtEW6ekNTQgCEZWZIc5K2Syfw47S3TJbffM5ZtKx3pSmUv0F4WFpprJAdY9byCq0xyk4RpCS1jL9FmEQSFeEGHqAf_yBa8WUqysqhcHMBQvTMWIVGrkWgV6tZEC8d8k8MuWNcNRdimEw-MqW0H3ZKE6AxV_8OpJtgJei6Tpa5eLHVhejqBvog==

[31] Standard Patent Glazing. Glass Performance Data Sheets and Specifications. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQFDdhDmbuis130_qqOAiF6KEZZkYYqTV-BotvchnJ4c7aIs3YQkH6XTPV5lwGFEQPk8s-0zEGJN3Rv3yXJnUCOWCNTXCVzPz3wMTSZ8JHWCKHGGgZdTvLNin-DrafVRFwdLyBrZtGq9qMI3QoAjnC4zGR3nlCVD4VG9pw5U6mgkZg==

[32] ResearchGate. (2023, December 15). (PDF) Fabric first: is it still the right approach?. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQFyCfkbiPMTd0mOZmxBW20ym8QL_M83Jxa_7a0D644UWIUkueI_WCwXPdJUM3Val-TGF4CEQ0UfHrxBUSjOMheRfS3O1IhfQGMagP8my_hYcCAuo8D_F8p4R4Rmw7P8SO1AYn7Si7eaw0Zu_MtCJixmAoL78RK6iQsCW5YasjO9lkvJnHgTGpXa_SLTsojYRQfoBrg296534g==

[33] Sero. (2022, December 19). Retrofit: is Fabric First Really the Best Strategy?. Retrieved from https://vertexaisearch.cloud.google.com/grounding-api-redirect/AUZIYQG0169ArJsMgkHHOmN79grr6URHW3dYCLttVnrEga786Anse1-0neAtmra6sYfYcdRcnmeJrkc1xEsn4opuBUKi93cuyN5hSv7jqDAFzvUmzEMSe1T64lzlBcTpboN7n0k_SznM-JAmrq3VpfS5FRSjQJ0WMZnTmeFIYCeRKQHxDmrp77vPIEhf0IkH7mJ6rtJRi9RVesEJGa2RiYkhWiXtqxWe-Rj2R40Q=

The discussion on balancing embodied carbon with operational savings is vital. Have you explored strategies such as using locally sourced, bio-based materials to minimize transportation emissions and support regional economies, while still maximizing long-term energy efficiency?

Absolutely! The commenter raises a crucial point about sourcing. We’re seeing great strides in using locally sourced, bio-based materials. They offer lower embodied carbon and boost regional economies. The key is ensuring these choices still deliver optimal long-term thermal performance. There is a lot of interesting innovation happening in this space.

Editor: FocusNews.Uk

Thank you to our Sponsor Focus 360 Energy

The report’s discussion of thermal bridging is critical. It would be interesting to explore innovative materials or techniques, such as aerogels or vacuum insulation, specifically designed to address complex geometries and minimize heat loss at these junctions, particularly in retrofit scenarios.

That’s a great point! Exploring advanced materials like aerogels and VIPs to tackle thermal bridging in complex geometries, especially retrofits, could significantly boost performance. Has anyone had experience with these in older buildings? Would love to hear about practical applications and challenges you’ve encountered.

Editor: FocusNews.Uk

Thank you to our Sponsor Focus 360 Energy

Considering the detailed discussion of thermal bridging, how do current building codes adequately address complex, three-dimensional thermal bridges, and what innovative modeling or simulation techniques are being developed to better predict and mitigate their impact on overall building performance?